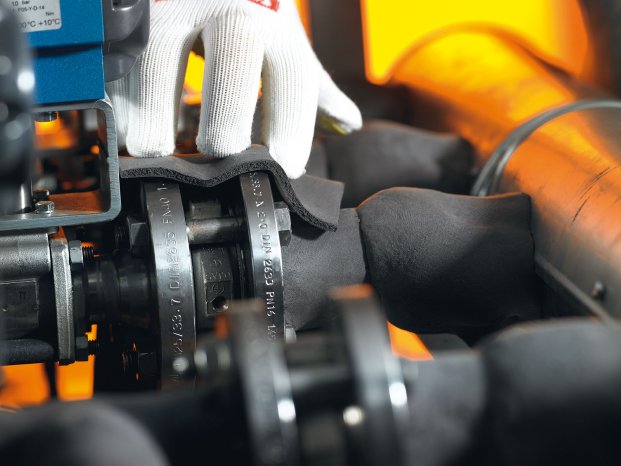

Conti® Thermo-Protect is the ideal insulation solution for complex or flexible ducting and piping systems. Already the winner of several awards, the ContiTech product steps into the breach when conventional insulation materials fail. The plastic, ductile mass can quickly and easily be applied to couplings and valves that proved impossible to insulate in the past. Conti® Thermo-Protect reliably protects against heat loss and considerably cuts energy costs - whether in heating systems, thermal oil installations and vulcanizing presses.

Now self-vulcanizes at over 80°C

Conti® Thermo-Protect can be used at ambient temperatures from -50°C through +250°C. And using system or machine heat, Conti® Thermo-Protect now self-vulcanizes at temperatures above 80°C. It is self-adhesive, water repellent and self-extinguishing, UV-resistant, and weatherproof. And ContiTech Elastomer Coatings is already at work on the next generation, which will target specific temperature ranges.

Pastes, hoses, and molded products added to the product portfolio

The product portfolio is also being extended: Alongside non-cured slabs suited to individually and flexibly insulating flanges, couplings, and complex ducting, as well as machines and other systems, ContiTech has now added other application variants to its range.

The most recent additions are particularly flexible and robust CTP hoses - pre-crosslinked hose insulation. The product range also includes pre-slit hoses in various thicknesses and closed insulation on reinforced hoses.

CTP molded products are also new to the range. The prefabricated and linked molded products are available for quickly insulating valves and couplings. Various precut sizes cover the most common standard couplings sizes; special designs are possible on request.

Dispensing the new CTP paste is particularly easy. Available in cartridges, the unvulcanized insulation material is ideal for closing up slits and clearances. The paste is also the perfect addition when using CTP boards.

Also new to the line-up are CTP accessories. They expand the range of CTP application possibilities. Systems and adhesives for securely sealing molded products are also envisioned.

Huge demand for insulation materials

"In an age when climate neutralization and cost optimization are important issues, there is a huge global demand for insulation materials in all industries. The ISO in Cologne is one of the biggest industry events in Europe. It attracts a broad international audience and is thus the ideal marketplace for us to show off the wide range of applications for our Conti® Thermo-Protect insulation system," says Hans-Peter Paulsen from Business Development CTP at ContiTech Elastomer Coatings in Northeim.