- Smaller, more powerful, and lighter weight than previous systems

- Ideal for drives with timing belts and chains

- Service network

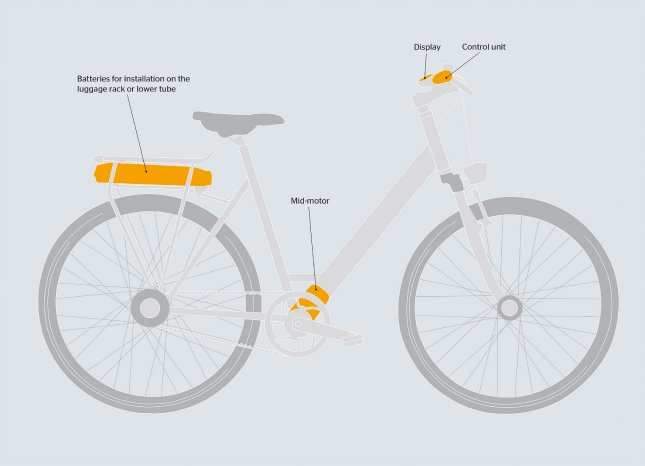

Continental is strengthening its commitment in the growth market for e-bikes and pedelecs. At the Eurobike trade fair in Friedrichshafen (August 28 to 31, 2013, hall A6, booth 303), the company will be showcasing a complete drive system comprising a mid-motor, display, control unit, and battery. This modular system is positioned in the premium segment and is smaller, more powerful, and weighs less than other concepts currently on the market. The motor itself is small, weighs only 3.4 kg and is integrated directly in the frame. As a result, the system engages exceptionally smoothly, giving a much more comfortable ride. Bicycle manufacturers can configure the system according to their needs. For example, batteries for installation on the luggage rack or lower tube can be ordered and are also available in different capacities. Continental will set up its own service network for actively supporting OEMs and distributors.

"Our customers in the bicycle industry benefit from a benchmark-setting, optimally attuned system comprising high-quality components," says Regina Arning, head of the Industrial market segment at the drive specialists ContiTech Power Transmission Group. The company, which belongs to the automotive supplier Continental, has been developing and manufacturing drives for cars, motorcycles, and the mechanical engineering industry for many decades now. "Our strength is system integration, which is essential in bicycles due to the construction of the frame. Manufacturers who use the drive system from Continental will not have to change the length of the standard frames." Continental has brought the system to production maturity together with its partner Benchmark Drives, and they will also market it together. The aim is to achieve a double-digit share of the market for e-bikes and pedelecs.

CONTI® DRIVE SYSTEM further optimized

At last year's Eurobike, both companies had presented the CONTI® DRIVE SYSTEM, which is fitted not with a chain but with a timing belt and special drive pulleys. What makes this system special is the tooth profile, whereby the size of the teeth ensures excellent protection against belt jumping. In addition, less pre-tensioning is required than with other systems, which reduces stress on the components and makes pedaling much easier. "The extremely positive response from the bicycle industry to this system has motivated us to strengthen our commitment in this industry," says Arning. "Continental has been supplying bicycle tires for decades now and knows the industry and its needs inside out. Customers of our drive systems benefit from this know-how." Continental will also be showcasing the second-generation CONTI® DRIVE SYSTEM at Eurobike.