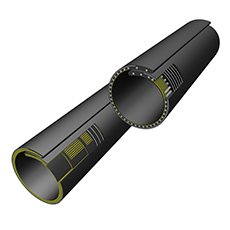

The larger diameter of the MegaPipe offers two significant advantages. Firstly, the larger belt width of up to 3,200 millimeters enables a significant increase in the capacity of conveyor systems by more than 100 percent compared with standard closed-trough belts. With its latest development, the ContiTech Conveyor Belt Group also provides an ideal product solution for transporting coarse-grained material. MegaPipes can handle material with an up to 50 percent larger lump size than conventional closed-trough belt systems. MegaPipes are available both as textile and steel cord conveyor belts. This allows for the best possible adaptation to long distances with curves as well as to the requirements of the material being conveyed.

Significant potential for minimizing expense

MegaPipe opens up completely new possibilities and application areas for closed-trough conveyors. While crushed mineral ores, rock or coal have to be laboriously reduced in size for transportation with standard closed-trough belts, MegaPipes enable transportation directly after the primary crusher. In opencast mining, it is even possible to dispense with the use of trucks in hauling material away for further processing. The conveyor belts can also be used in industry to transport coarse-grained material. According to Dr. Andrey Minkin, application engineer at the ContiTech Conveyor Belt Group: "As far as I know, no other product to date has possibilities of a comparable nature." The larger belt widths do not impact on the center distance of the closed-trough conveyor system. In theory, a center distance - and with it an entire length - of over ten kilometers can be achieved with a steel cord MegaPipe. This is the same as for conventional long-distance installations.

Eco-friendly and flexible

Apart from the width of the belt, ContiTech closed-through belts made from high-quality flexible material offer significant advantages when used to transport dusty material on complicated routes. While the angle of inclination on troughed conveyor belts does not generally exceed 20° - depending on the properties of the material - and curve radii remain very large, a closed-trough belt makes possible sharp 3D curve radii and angles of inclination of up to 35°, depending on the nature of the material hauled. The material is shielded from the environment during transport. This protects ash, cement, minerals, coal, rock parts, and similar material from external influences while at the same time ensuring that the conveyance operation is particularly eco-friendly and does not release dust into the environment. "This is so because the belt rolls up," explains Wolfgang Fischer, application engineer at the ContiTech Conveyor Belt Group. The outside edges of the belt overlap throughout the transportation operation. Only when taking up and delivering material do the closed-trough belts open up and assume the shape of a conventional conveyor belt.