The manufacturer recommends checking and, if necessary, replacing the timing belt every 90,000 km, and then every 30,000 km.

The procedure takes 2.5 hours.

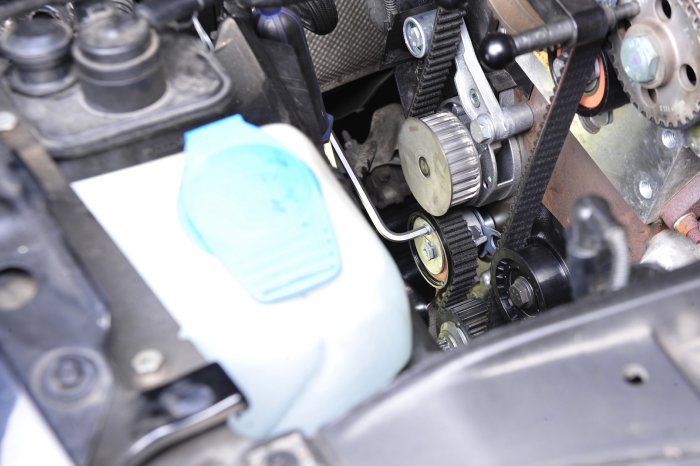

Tip: When the timing belt is replaced, the tension pulley, idler pulley, tensioner and water pump should also be replaced.

Fitters require the following special tools:

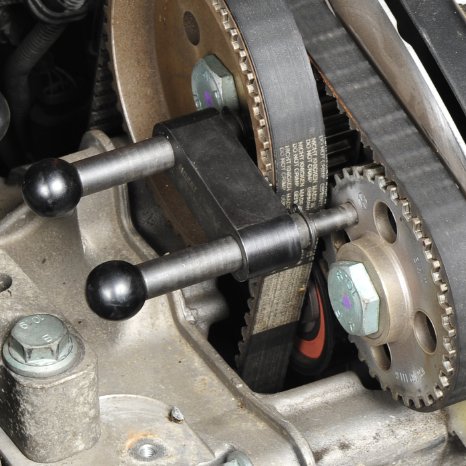

1. Camshaft locking tool (except ARC/ARR/AVY) - VW no. T10016

2. Camshaft locking tools (ARC/ARR/AVY) - VW no. T10074

3. Arrester for crankshaft belt pulley with accompanying bolts (except ARC/ATN/AUS/AVY/AZD/BCB) - VW no. T3415

4. Arrester for crankshaft belt pulley (ARC/ATN/AUS/AVY/AZD/BCB) - VW no. T10028

Preparatory work:

- Identify the vehicle using the engine code.

- Disconnect the vehicle's battery.

- Do not turn the crankshaft or camshaft when the timing belts have been removed.

- Remove spark plugs so that the engine can turn more easily.

- Turn the engine in the normal direction of rotation (clockwise).

- Turn the engine ONLY at the crankshaft sprocket and not at other sprockets.

- Comply with all tightening torques.

Removing the camshaft belt:

1. Jack up the front of the vehicle and support it.

2. Remove the upper engine cover, the complete air filter, the upper timing belt cover and the steering oil storage tank (do NOT detach the hoses).

3. Turn the crankshaft to the right to TDC (OT) in the first cylinder. The control markings on the crankshaft belt pulley must be aligned.

4. Check whether the locating holes on the camshaft sprockets are aligned. If they are not aligned, turn the crankshaft to the right a further complete turn.

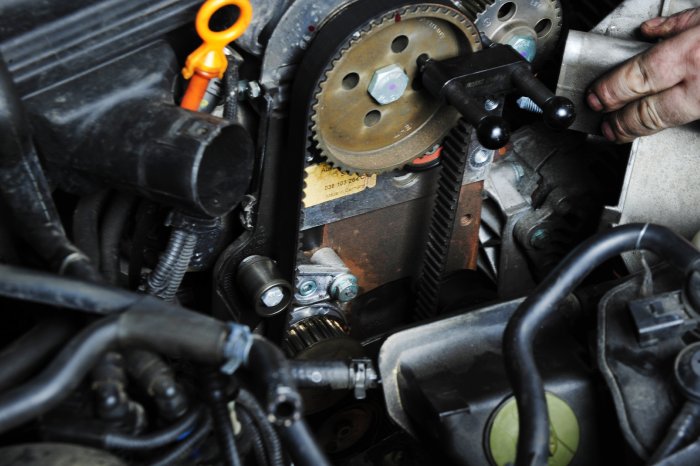

5. Insert the locking tool at the camshaft sprockets (Fig. 1): Tool no. T10016. If the engine code is ARC/ARR/AVY: Tool no. T10074 6. Remove the right-hand engine mount (Fig. 2), the holder for the right-hand engine mount and the lower engine cover on the right.