- Tester ensures multiple V-ribbed belts are changed at right time

- Laser for accurate alignment measurement

- Tension tester for timing and multiple V-ribbed belts

- Videos demonstrate operation

It's indispensable: workshops are increasingly dependent on the assistance of diagnostic technology for servicing and repairs. Devices from the ContiTech Power Transmission Group enable auto mechanics to identify and repair belt drive faults easily. The tools available are a belt wear tester, a laser for alignment measurements and a tension tester.

Checking Wear

Multiple V-ribbed belt wear - as a result of the effects of heat, deposits and operationally induced abrasion in the ancillary component drive - is not always visible with the naked eye. ContiTech's Belt Wear Tester (BWT) reliably detects the degree of wear by checking the profile geometry of the individual ribs. This enables professionals to determine precisely whether the multiple V-ribbed belt needs to be changed. Important: This test does not replace the specified servicing intervals, but assists workshop professionals in assessing the belt condition. The tester comes complete with instructions. There is also a product film showing how to operate it. The video is available online at www.contitech.de/aam-en in the 'Service & Accessories' section. It can also be accessed on YouTube.

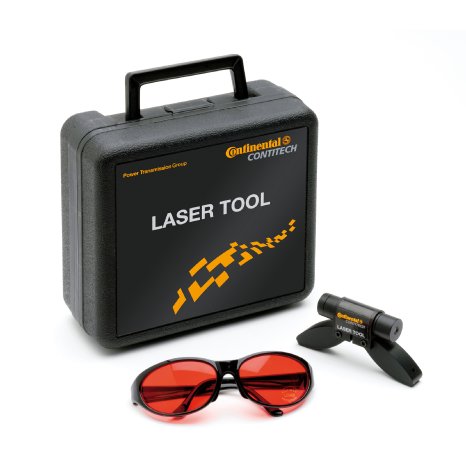

Laser for Reliable Alignment Measurement

The LASER TOOL measures whether all the pulleys in the belt drive are aligned. This provides a fast and dependable means of identifying alignment faults in the belt drive. A correct diagnosis is essential for rectifying faults in order to guarantee trouble-free operation of the belt drive. Incorrectly aligned belt pulleys are frequently the cause of noisy multiple V-ribbed belt drives or premature wear of the belt. The ContiTech LASER TOOL can be used for all automotive multiple V-ribbed belt drives, including those with synthetic pulleys. A product video is also available for the LASER TOOL.

Measuring Belt Tension

The correct tension is of great importance for the belt drive. Fitters must not rely on their intuition here; they need to work on the basis of precise figures. The Belt Tension Tester Hz (BTT Hz) accurately measures the tension of timing and multiple V-ribbed belts in accordance with the most up-to-date method - frequency measurements in hertz. Operation is very simple, via just two buttons. An integral self-calibration system increases the measurement reliability.