- German-Chinese joint venture Benecke-Changshun Auto Trim is one of the leading companies for motor vehicle surface materials in China

- Partner of choice for automotive manufacturers and highly sought-after government advisor

- Joint venture set to expand

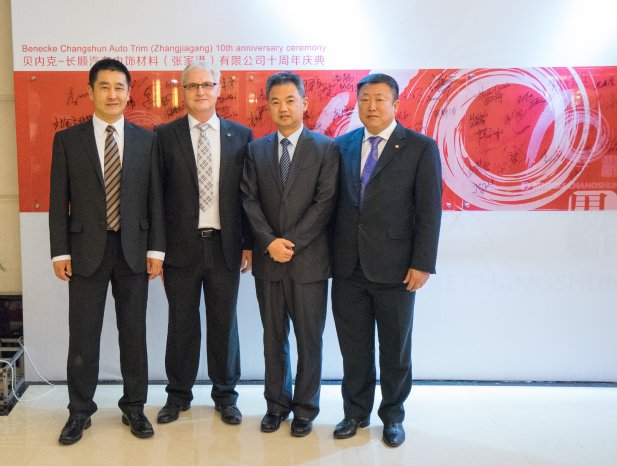

- Partners to celebrate the 10th anniversary on May 20-21 in Zhangjiagang

Benecke-Changshun Auto Trim (Zhangjiagang) and its partners celebrated ten years since the founding of the joint venture. Together with the employees, customers, partners, and local politicians, they celebrated a success story - one that looks set to continue for a long time.

For the past ten years, the Continental ContiTech business unit Benecke-Kaliko and its partner company, the Jiangsu Changshun Group, have been writing their own German-Chinese success story. "We can look back in pride on what we have achieved together and on our long and amiable partnership, which is the basis of our current outstanding market position for high-quality, low-emission vehicle interior materials in China. We intend to continue strengthening this position," says Dr. Dirk Leiß, Chairman of the Executive Board of Benecke-Kaliko AG. "As one of the world's leading manufacturers, it is our goal to be wherever our customers need us - and this is a promise that we have kept for the past decade now. This country is one of our key global markets and, as such, a cornerstone of our economic success. The deep-rooted trust of our customers and partners in industry, trade, and research encourages us each and every day to further strengthen our long-term commitment to China."

The company currently operates two production and development locations in China. Today in Zhangjiagang, where Benecke-Changshun Auto Trim was founded in 2005 and which was the first location, 450 employees work on the manufacture of foils for automotive interiors exclusively for the Chinese market. "Benecke-Changshun Auto Trim is one of the leading chemistry companies, which focuses on eco-friendly products and innovative technology. In cooperation with the Continental Corporation, the joint venture not only gains the advanced technology to produce high-quality products, but is also able to pursue market trends and provide a fast response to the market. This is a very crucial factor to success," says Dr. Renfa Gu, Chairman of Jiangsu Changshun Group.

At the end of 2015, operations will commence at the new plant in Changzhou, where up to 250 employees will produce Acella Eco in the future. This cover material for car seats, door panels, and consoles is a top-seller in China. Acella features particularly low emissions and non-allergenic properties. This has generated so much customer interest that Benecke-Kaliko has spent around €40 million on the construction of a second plant in China. This is the biggest investment in the company's history and part of the ongoing expansion strategy on the Asian market.

Local expertise and development, sustainable production

"This new plant is our response to the very high demand for our products and solutions on the Chinese automotive market," says Benecke-Changshun general manager Uwe Wüst. Automotive manufacturers in China are increasingly demanding motor vehicle interior materials that are both high-quality and eco-friendly. In this way, automotive manufacturers are not only heeding the wishes of car buyers but also complying with the Chinese government's objective of improving air quality inside vehicles. "As a specialist in low-emission surface materials, we are now also contributing our knowledge in an advisory role to the country's government. For example, we are helping to define standardized methods for measuring air quality in automotive interiors," says Wüst. The aim here is to avoid health impacts from solvents or synthetic materials. "Benecke-Kaliko is an international pioneer in low-emission interiors that are safe for human health. We are currently the supplier on the local market whose materials can completely meet the strict legal requirements, meaning that we are doing our bit to ensure that the air inside China's cars is healthy," says Wüst.

Benecke-Kaliko utilizes its global development knowledge and worldwide market presence to optimally serve individual customer needs with local designs over short transport routes. Thanks to this local expertise and uniform material and process standards, Chinese customers receive the same product, engineering, and service quality as customers on every other continent. "For the past ten years, our customers in China have benefited from the fact that we invest sustainably in innovation and quality," says Leiß. Sustainably particularly in relation to the production conditions. "This is because our understanding of a future-oriented commitment involves not only producing eco-friendly products but also, and above all, engaging in energy-saving and environmentally friendly production. This means the greatest possible level of protection for people, the air, and water. This benefits us as a company, our employees, and the local population where we are based. It also benefits our business customers and partners."

Equally strong is Benecke-Kaliko's commitment to acting as a fair and responsible employer promoting the best-possible working conditions at all international locations. This includes not only investing in training and promoting young talent but also implementing industrial safety and health management measures.

All these factors are what make Benecke-Kaliko so successful in the field of automotive interior foils. In 2014, the company employed more than 2,250 people in development and production at its six locations worldwide, most of them in the four plants in Zhangjiagang (China), San Luis Potosí (Mexico), Hanover, and Eislingen (both Germany). On November 1, 2014, Benecke-Kaliko acquired two plants run by the Belgian Mecaseat Group in Pamplona (Spain) and Wągrowiec (Poland) with almost 140 employees. Sales last year amounted to €469 million.

10 years of Benecke-Changshun - milestones of a success story

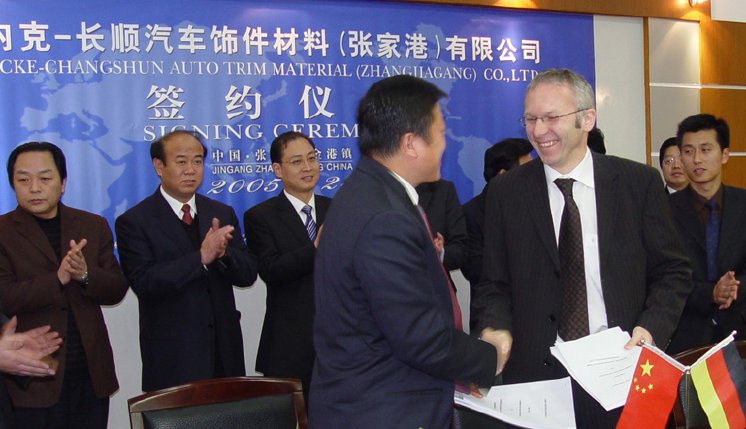

2005: Benecke-Kaliko and Jiangsu Changshun found the joint venture Benecke-Changshun Auto Trim. Construction begins on the Zhangjiagang plant.

2006: Start of production in Zhangjiagang.

2008: Benecke-Changshun becomes one of the leading manufacturers of PVC foam laminates in China.

2009: The Zhangjiagang plant expands production to include PVC composites.

2010: The Zhangjiagang plant produces more than three million square meters of cover materials.

2011: Benecke-Changshun is the first company in China to use water-based lacquers in the production of surface materials.

2012: Establishment of the Technology Center which further develops production processes and products for the Chinese market.

2012: Benecke-Changshun is certified as a state-level enterprise.

2013: Benecke-Changshun achieves several invention patents: automotive interior materials manufacturing process, automotive interior leather with titanium dioxide pigment color paste preparation method, special PVC formulation of interior.

2013: Awarded the prize for the best material innovation by the world-renowned online platform Gasgoo.

2014: Start of mass production of TPO foils in Zhangjiagang. The annual capacity of the plant now stands at ten million square meters of compact foil and foam laminates (Tepeo) and eleven million square meters of PVC materials (Acella Eco).

2014: The "Technology Center" in Zhangjiagang receives an award from Jiangsu Province in the "Foreign Research Center" category.

2014: The Auto & Parts magazine presents Benecke-Changshun Auto Trim with the Chinese "Environmental Production Award" in Shanghai for the environmentally friendly cover material Acella Eco green.

2015: Construction begins on the new plant in Changzhou, for which Benecke-Kaliko and Jiangsu Changshun found the joint venture Benecke-Changshun Eco Trim Co., Ltd. In the first stage of expansion, up to 250 employees in Changzhou can produce ten million square meters of PVC surface materials for motor vehicle interiors every year.

2015: The Design Center is opened in the Zhangjiagang plant, which is designed to support customers initially in China and Korea and later customers from the entire ASEAN region (Australia, India, Japan, etc.).