The HighLight 1000FL is an OEM fiber laser that delivers 1 kW of continuous-wave fiber-coupled output at 1 µm wavelength. This laser employs a unique, modular design utilizing semiconductor laser bars in a single pump aggregation module, without the complexity and service issues of splices or gratings. Final laser output is from a 50 μm fiber. This approach is specifically intended to provide systems integrators with greater machine design flexibility, reduced system development time and lower overall system complexity. For end users, it translates into greatly simplified field service. This design also makes the HighLight 1000FL less susceptible to optical feedback, which is particularly important when cutting highly reflective metals. To enable further operational flexibility, the integrated onboard electronics implement fast pulse modulation (up to 4 kHz) in the same manner as is currently used in CO2 based cutting systems.

The HighLight 1000FL is primarily targeted at cutting and welding a variety of metals, such as mild and stainless steels, copper, aluminum, brass, titanium, and aluminum-magnesium. With 1 kW of output power, the HighLight 1000FL is ideally suited for metal thicknesses of 0.5 mm to 3 mm - a range representing 80% of all cuts made today - at the fastest possible cutting speed of any laser technology.

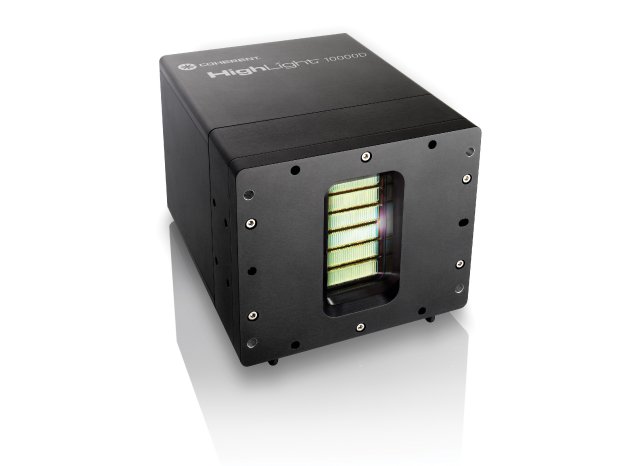

The HighLight 10,000D is a high power, direct diode laser system that produces 10 kW of output, with free space beam delivery. This preserves the inherent brightness of the diode laser source and enables the use of an optical system with a large (275 mm) working distance. The HighLight 10,000D outputs a line beam, with a wide range of length options, ranging from 6 mm to 36 mm. Together, all these factors translate directly into enhanced laser capabilities in industrial processing applications. Specifically in cladding, it yields a higher material deposition rate (greater than 10 kg power per hour), allowing the laser to cover large areas in a short amount of time. Similarly, in heat treating, it enables processing of larger areas in a single pass. In addition to high performance, a variety of options are available with the HighLight 10,000D to enhance ease-of-use. These include an air knife, which protects the laser from back-splattered material, heat and returned laser light, thus extending system lifetime. A pyrometer for monitoring work surface temperature enables closed-loop control of laser power during heat treatment and cladding. Features to enhance productivity include a laser system control unit with a simple graphical interface, and remote diagnostics that allow system operation to be analyzed by Coherent service personnel over the internet.