Because it is unavoidable that big currents cause a skin effect (displacement effects) in the conductor, Roebel Bars are used to have a higher current carrying capacity per cross-section.

They consist of periodically twisted rectangular lines (Continuously Transposed Conductors), which together form an overall conductor bar.

To ensure that these twisted lines remain mechanically robust and have a good thermal dissipation of the occurring heat loss in the single wires, these Roebel Bars are impregnated.

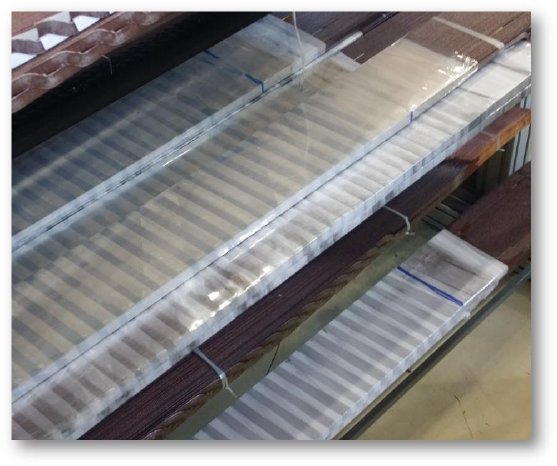

As a preparation for the thermal curing of the impregnating varnish, Roebel Bars are wrapped with a release film. This film prevents that the melting varnish litters the oven walls during hardening.

The ETFE-film CMC 77707 is highly suitable for this process. The slightly stretchable film - spirally wrapped around the Roebel Bar - nestles to the rod and seals the CTC.

In this way the resin cannot be pressed out during the heating process and the system is protected against soiling.

Due to the smooth, resistant surface (similar to Teflon) the film can be removed without any marks (silicon residues) after baking. Since ETFE is transparent, visual quality control through the film is possible.

Just like all products by CMC Klebetechnik, the CMC 77707 is available in individual width.