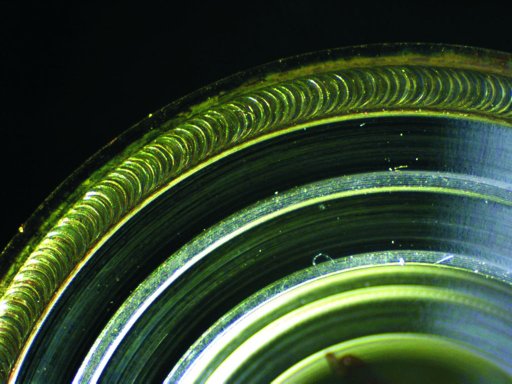

The TOLAS 1 by arteos uses a completely new developed, pulsed ND:YAG laser with a nominal output of 5 W and a non-visible, infrared 1.064 nm wavelength. The spot diameter of the laser beam can be electrically adjusted between 10 µm and 50 µm. This small spot diameter only melts small areas of the materials that are to be welded. This not only reduces the thermal stress of the components, it also prevents the objects from warping. Warp-free welding is a big issue when for instance a filmy foil is to be welded to a relatively thick metal ring.

As no application is identical to any other, arteos has developed a wide range of accessories for the TOLAS 1 micro-welder: The palette stretches from grippers to magazines, positioning aids, feeders, and microscopic cameras to protection chambers for vacuum welding or welding in a protective gas atmosphere as well as customer- or application-specific solutions.

While developing the TOLAS 1, arteos attached great importance to an intuitive user interface. The most important features are controlled by means of a touch-screen. With a footprint of 400 by 500 mm (approx. 16“ by 20“), the micro-welder only occupies the area of three sheets of typewriter paper. The electric power requirement is 1 kW; interfaces for external cooling are provided. The built-in stereo microscope with its 16-fold magnification allows for an immediate quality control of any welding processes. Thanks to the USB interface, settings and data can be read out or imported easily.

In addition t

o medical engineering, the TOLAS 1 micro-welder is ideally suited for applications in sensor manufacturing, in precision mechanics or for manufacturing electronic components like power semiconductors or power modules. Optionally, the TOLAS 1 can also be used for drilling, cutting and structuring applications.

More information can be found on the internet: http://www.arteos.com