Fiber reinforced plastic (FRP) is a preferred material for producing medical device structures such as prosthetics and orthotics due to its weight-related properties and fatigue resistance. While Germany leads in lightweight medical engineering research, the still largely manual production is often being outsourced to low-wage countries or result in high costs for the patients in need. As many components are customized to the actual patient, an automation of the production was not possible to date with current conventional FRP manufacturing technologies.

In this context, the joint R&D project “Patch2Patient”, funded in the BMBF program “Production for Medical Technology – Economical and of the Highest Quality (ProMed)” was launched in 2019. The goal was to develop a novel process chain for the automated production of fiber composite components in medical technology and implement its basic elements. In addition to the developed cloud-based data exchange platform, patient-specific data acquisition and virtual test methods, the work focused on automated laminate and machine data generation as well as technologies for multi-material processing with Cevotec’s FPP technology.

“By providing an efficient planning, data processing and manufacturing workflow, the value chain for components such as prosthetics and orthotics can be strengthened in high-wage countries in Europe.”, states Dr. Florian Lenz, Technical Director of Cevotec. “In addition, many of the technologies developed can also be used in other industries, such as aerospace, so that further growth of European manufacturers of composite components can be supported.”

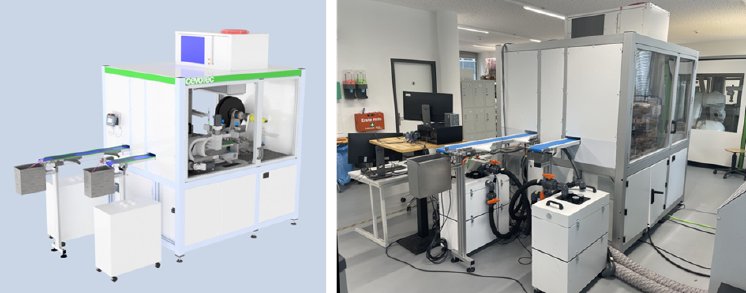

Cevotec focused on analyzing possible approaches to incorporate patient data into their laminate design software ARTIST STUDIO. In addition, they have developed a dedicated material feeding and cutting unit (FCU) as a key enabler for an FPP process suitable for the efficient and economical production of medical composite products. This FCU is capable of handling different fiber materials and processing patches of variable lengths. Besides regular carbon and glass fiber slit tape material, the FCU is also able to handle especially cost efficient towpreg material as well as special fiber materials with improved fatigue and impact resistance.

This research and development project was funded by the German Federal Ministry of Education and Research (BMBF) within the “The Future of Value Creation – Research on Production, Services and Work” program (funding number 02P18C090 to 02P18C096) and managed by the Project Management Agency Karlsruhe (PTKA). The author is responsible for the content of this publication.