Following the successful market launch of the Fiber Patch Placement system SAMBA and the matching software ARTIST STUDIO, Cevotec has initiated the next development steps. Until now, the SAMBA system focused on the production of complex 3D preforms with a design space of about one cubic meter, but the attention of the Cevotec engineers is now directed to larger dimensions. "Fiber Patch Placement as a manufacturing concept is almost arbitrarily scalable," emphasizes Felix Michl, CTO of Cevotec. For high-volume production with Fiber Patch Placement technology, production cells will be able to process 15 kg of fiber material per hour. Integrated in a production line with several cells, the capacity, even while working on highly complex components, increases to more than 100 kg per hour - per request also as hybrid systems processing carbon- and glass fiber simultaneously.

Tailored to the requirements of development departments, research facilities and smaller serial productions, a special SAMBA version produces patch-based preforms in lower quantities. This allows for a low-investment entry into the patch technology and enables developers to continuously work on components without occupying precious production time of a series production system. The price for this system starts below 150.000 Euro.

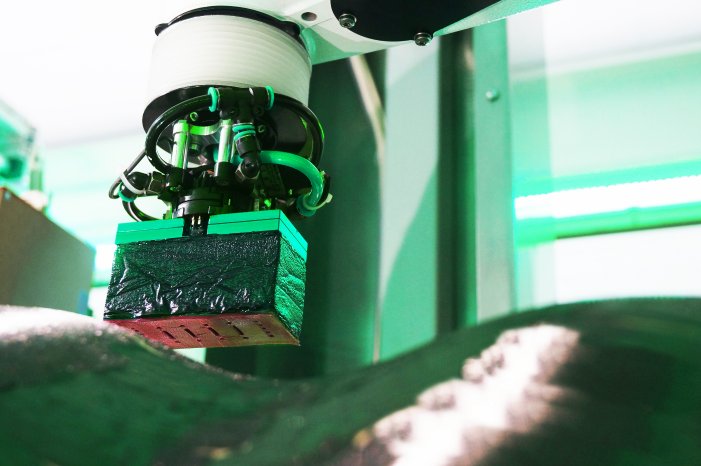

Cevotec is also working on a new system type that will enable manufacturers to process pre-impregnated fibers such as M21 material on the basis of Fiber Patch Placement technology. “When processing dry fibers, the patch gripper heats up the bindered patches before placing them on the mold”, explains Felix Michl. “When working with prepreg patches, the substrate or the mold is pre-heated at the position where the next patch is to be applied.” This version of SAMBA is intended to primarily meet the requirements of the aerospace industry, which also benefits from the very accurate fiber positioning and the excellent mechanical properties of patch laminates.

Cevotec at CAMX

CAMX Award Pavilion and booth R92

Cevotec at Composites Europe Stuttgart

Hall 4, booth C75