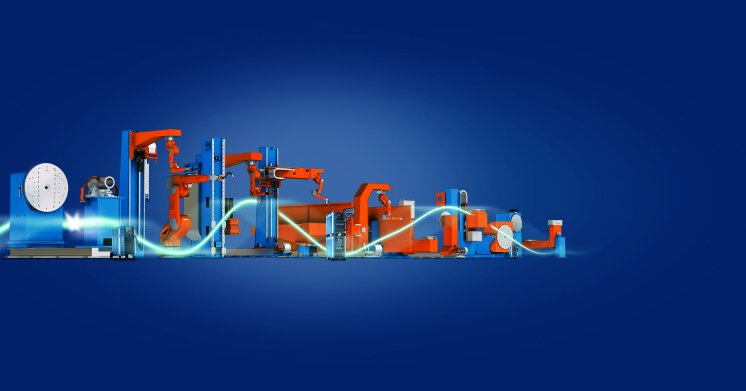

The focus of the CLOOS exhibition booth is on an automated robot system which is equipped with an automated torch changing system. No matter if thick or thin, steel or aluminium – here you find the right welding process for every product requirement. The welding specialists will present the new Tandem Weld generation for process-safe and very quick and comfortable welding. With the Cold Weld process an alternating current produces a very special pulse form, which brings about an extremely low heat input. The Laser Hybrid Weld process is the combination of a laser beam with a MIG/MAG welding process in one common process zone. thus using the advantages of both processes. The Narrow Gap Weld technology offers a particular economic efficiency for welding thick-walled component parts.

Avoid production downtime by an automated change of consumables

Another highlight is the new fully automated current tip and gas nozzle changer SpareMatic which allows non-stop welding with operative components. When the welding robot needs new nozzles, the automatic current tip and gas nozzle changer comes into play. The changer takes the torch consumables and replaces them for new ones. Due to its compact, modular design, the SpareMatic can be integrated into both new and existing systems.

High-quality power sources for manual and automated applications

Besides, CLOOS will present the wide QINEO model range of high-quality welding machines for manual and automated welding. The new QinTron inverter welding machine is characterised by a robust design, optimum ignition and welding characteristics and an excellent price/performance ratio. During live-demonstrations of manual welding trade visitors can experience the welding machines.