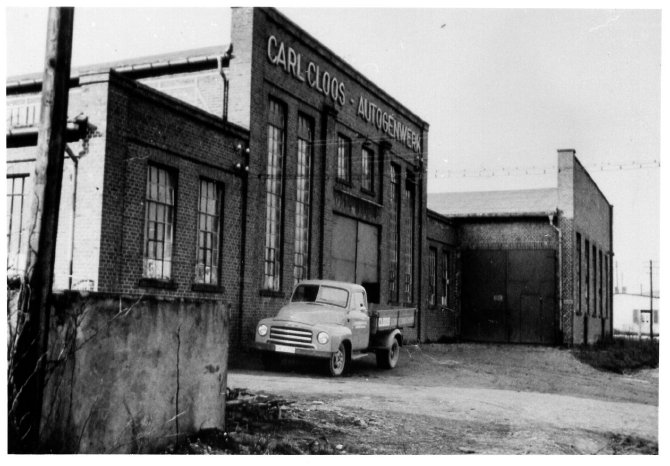

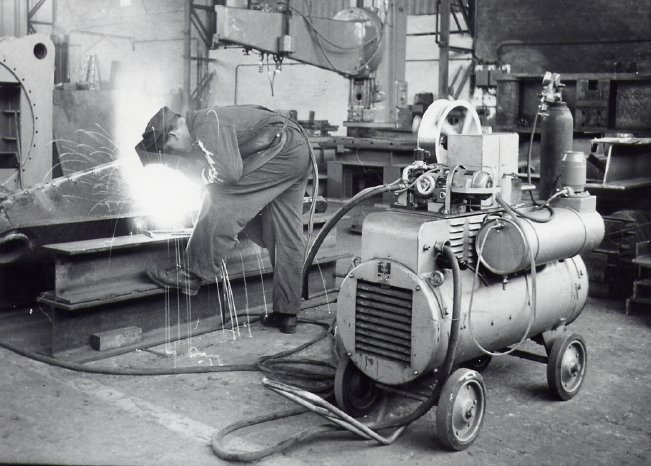

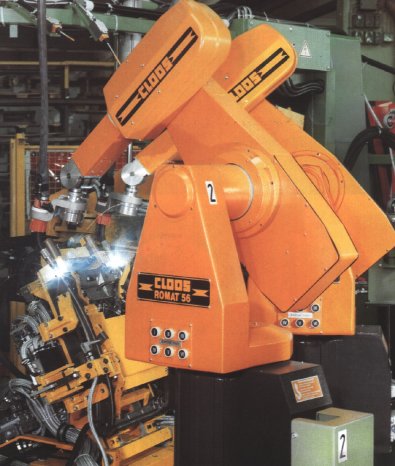

In 1919, the engineer Carl Cloos founds the company in Siegen-Weidenau and starts to manufacture acetylene gas generators and oxyacetylene welding torches. In 1924 they move to Haiger. In 1948, CLOOS starts to manufacture welding systems for stick electrodes. In 1956, Erwin Cloos presents welding with endless wire electrode for the first time at the Hanover Messe and introduces the CO2 shielded gas welding technology to the European market. In 1978, CLOOS uses industrial robots for shielded gas welding for the first time. Since 1981 CLOOS has constructed and produced their own industrial robots. Later, the company makes tandem welding and MIG/MAG laser beam hybrid welding ready for the market.

Today the CLOOS portfolio comprises simple, compact systems as well as complex, chained systems with automated workpiece identification and loading and unloading processes. The users benefit from the widely spread welding know-how as the welding specialists supply all relevant components from a single source.

In all business units, CLOOS pushes innovations. “The global demand increases for highly automated and intelligent robot systems where the single components of a welding system and master systems are linked with each other,” explains Thomas. “Therefore, we place our emphasis to the digitalisation.” The new CLOOS gateway C-Gate allows, for example, a user-specific visualisation, analysis and further processing of the operating and welding process data.

The traditional company CLOOS will celebrate the special company anniversary with a week of festivities in May 2019. On 7 May the welding specialists invite German-speaking customers and interested parties to an anniversary symposium and on 8 May the English-speaking customers are invited.