This includes classic operating data with target/actual comparisons including calculation and visualisation of the system effectiveness. All data and key figures can be analysed, visualised and processed via interface. Shift plans and component data can also be transferred from upstream systems via interface.

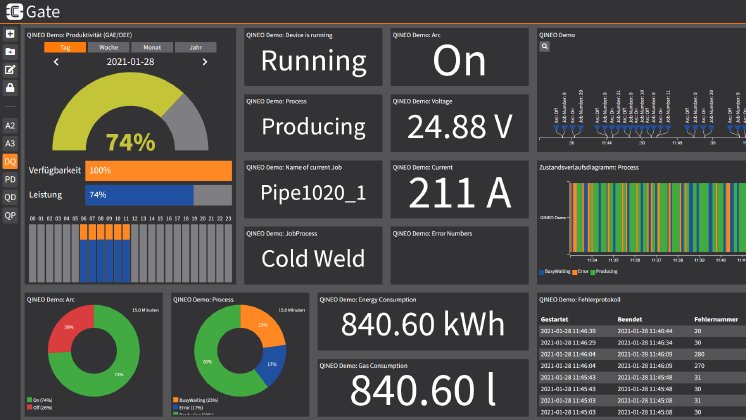

The user-specific presentation of information with customisable dashboards and reports enables detailed visualisation, analysis and further processing of the collected operating and welding process data. This allows users to monitor and control their production processes down to the smallest detail. With a manual QINEO welding machine, productivity can be determined, for example, on the basis of availability and arc burning time. Freely definable warnings early inform users about what happens in your production. Timely recognition of errors prevents unplanned downtimes and quality problems are solved directly.

With open interfaces (APIs) and standards such as OPC UA, the system can be easily and securely integrated into existing network and application environments (MES, ERP). Whether as central virtual server solution or as system-near edge-gateway implementation – all CLOOS robot systems and welding machines can be connected to the platform. Furthermore, existing QIROX robot systems and QINEO welding machines can be integrated. Thus the C-Gate supports users in their digitalisation and smart factory projects.

More information: https://c-gate.cloos.de/en/