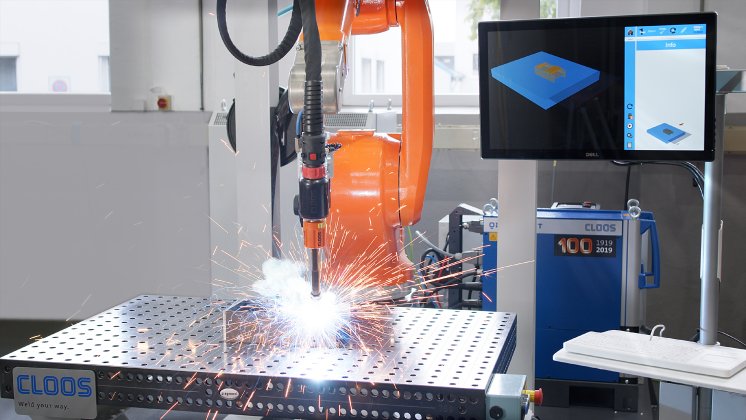

The operator freely positions the tacked workpiece on the robot working station. Then he starts scanning at the IRPS screen. The scanner mounted at a linear track scans the working surface of the robot system and saves the result. The IRPS converts the saved scanner data into a 3D model. Then the IRPS sends the completely generated robot program including all welding data to the robot controller. The operator starts welding via a button at the IRPS screen. Individual changes and parameter adaptations can be made easily and intuitively.

It is not necessary that the operator has a detailed welding and robot knowledge. Due to the complete programming automation, users benefit from an efficient and flexible welding production.

INSTANTpro B.V.

INSTANTpro B.V. Is a subsidiary of the Dutch family company Exner Ingenieurstechniek with more than 25 years of international experience in project planning, programming and maintenance of robot systems at the most different and well-known customers. On the basis of this know-how, Exner Ingenieurstechniek invests in further simplifying the robot automation and in making it more efficient. Exner employs a special team of developers of camera technology up to software specialists for artificial intelligence.