According to a survey by CADENAS, 43% of companies own no classification for their part master:

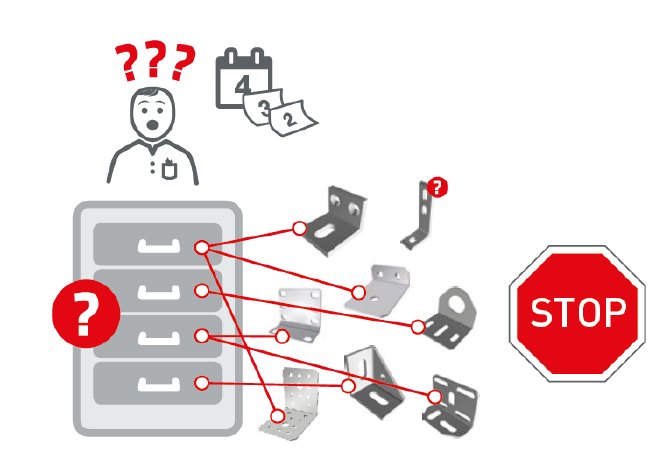

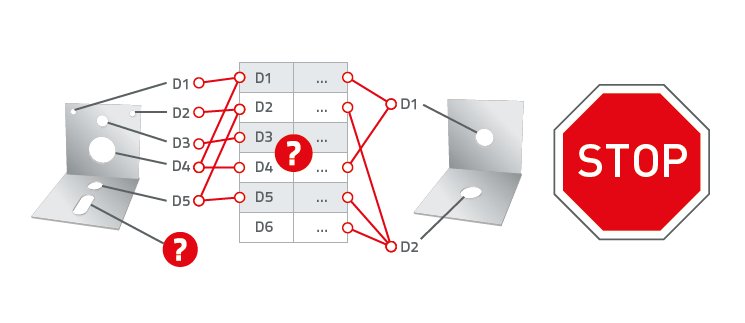

Many companies would like to benefit from the advantages of classifications, but come into problems already in the introduction stage. In classical classification the following obstacles must be taken into consideration:

Obstacle 1: Which system is the right one?

When introducing classification system manufacturers can be classify functionally (connecting, milling, drilling ...) or type-specifically (screw, nut ...).

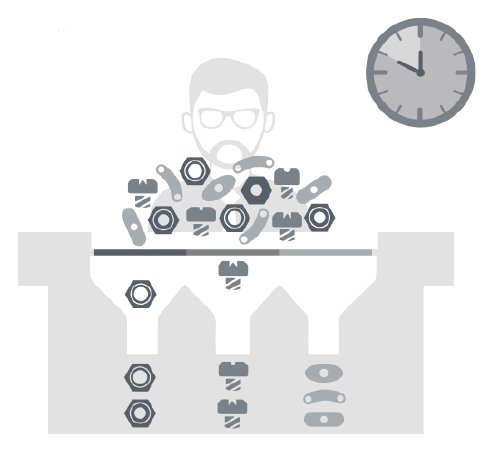

Obstacle 2: Time-consuming manual classification

The correct manual assignment of parts into an existing classification system is very time-consuming and costly. Therefore error rates are more likely to occur.

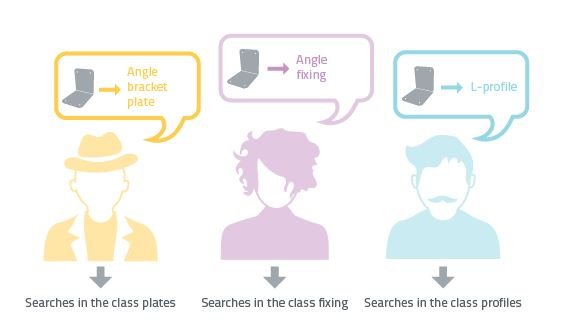

Obstacle 3: Little correspondence between the users & language barriers

Different employees have a different subjective perception of how a part should be classified correctly. According to expert estimates, the matching rate of a component classified by three different employees is around 30%.

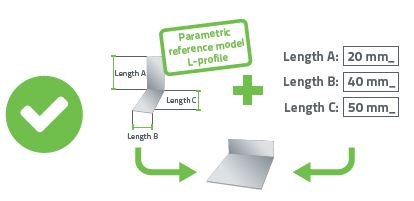

Classification through a reference model

Instead of labouriously manually adding each individual component to a specific class, Classification 2.0 allows for a reference model to be set in each class by its geometrical charachteristics. If for instance, an L-profile with certain dimensions is necessary, the system looks for parts that are geometrically similar to the parametrically prepopulated reference model.

In contrast to the traditional classification, there is no complex preliminary manual work necessary with Classification 2.0. The consideration of the geometry in the classification has the advantage that it is language-independent and thus much less prone to error. Because in the manual classification often occur problems since three employees use three different names for a component.

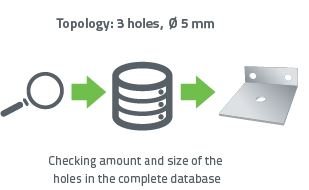

Ability to consider drill holes thanks to topology search

Some shortcomings of the conventional classification systems can also be compensated: If for instance drilling holes should be regarded in the classification, then additional classes would be actually necessary for the amount of holes (L-profile with 2 holes, Lprofile with 3 holes ...). Information about the size and arrangement of the drilling is anyway still not yet available.

With Classification 2.0, it is possible to take part classes (e.g.: L-profiles) as well as the amount and sizes of holes into account. With a topology search the system finds in your database the exact component with the necessary drillings for your design in an uncomplicated way.

More Information about Classification 2.0 and the Strategic Parts Management PARTsolutions can be found here.