This torque sensor comes into its own most particularly in fields such as precision and micro-mechanics, test bed equipment for electric motors, or in the automobile industry, where torque and the associated angular position and rotation speed are important process magnitudes. It is also very much at home in laboratory research and development projects in medical technology, in the chemical industry, and in quality control.

The signal from the full-bridge strain gage signal is digitized at the shaft itself, and is converted into a 0 to ± 10 V DC signal by a 16 bit D/A converter located on the stator. In light of the need to minimize the necessary servicing cycles, the power is supplied inductively while the measured signal is transmitted optically. As a result, the measurement is obtained without any wearing parts, and a high immunity to interference is ensured. The maintenance-free operation and the increased capacity to handle high rotational speeds make this series of sensors ideally suited to efficient application in industrial manufacturing and assembly equipment, where activation, adhesion, breakaway and tightening torques must be measured.

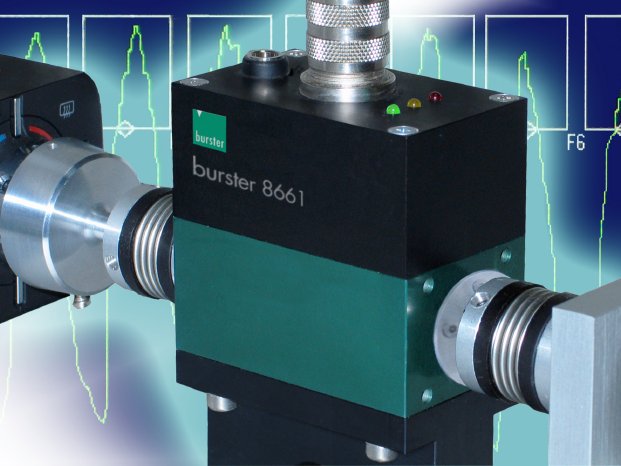

Continuous operation and a high dynamic range of up to 25,000 RPM are supported effortlessly by the optimized mechanical design. A high-resolution TTL output signal for the optional angular displacement and rotational speed measurement facilities is achieved through optical sensing of an incremental encoder disk that incorporates two offset tracks and four-edge sampling. An operating status display (green/yellow/red LED) gives the user a range of status information even from a distance. This greatly simplifies commissioning and function monitoring, as well as fault finding.

The USB interface and the PC-based software permit convenient operation away from mains power, as well as mobile application for field measurements, including visual display, archiving and logging of the measurements. A driver package for linking into the user's own programs is included free of charge. The redundancy of the power supply options, the unambiguous identification of the measurement and drive sides, the numerous options and plentiful accessories are key indicators of improved user-friendliness. This high-performance torque sensor is completed by the possibility of preparing traceable factory or DKD (German Calibration Service) calibration certificates for the sensor or for the measuring chain - even when delivery times are short!