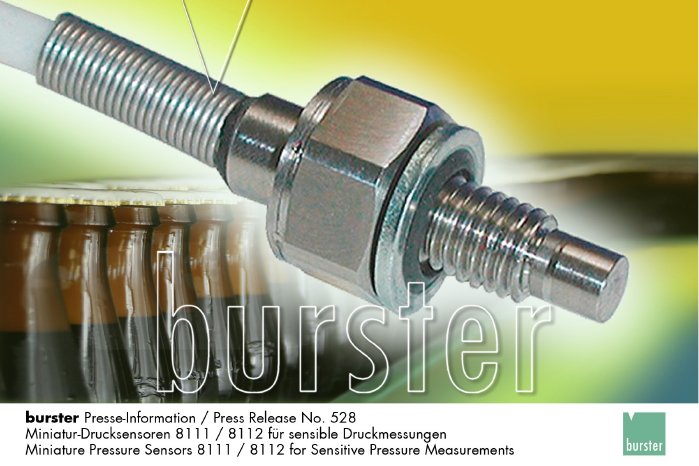

The miniature pressure sensors are equipped with a flush mounted diaphragm from diameter 3.6 mm with connecting M5 assembly thread. Thus they can be easily mounted and tightened with a sealing ring. The light weight of the sensors can be fully neglected within their surrounding structure. Their media touching parts as well as the housing are made of stainless steel or titan. Operating temperatures up to +200 °C are possible as well as down to -75 °C. Measuring ranges are available from 0...2 bar to 0...350 bar. The single components of the miniature pressure sensors are bonded in a laser welding process whereas the sensors are thus designed that the distorting forces arising in the sensor housing are decoupled from the measuring membrane. This results in stable measuring values and a high accuracy.

These qualities render the little all-rounders suitable for many trade branches. Representing all those simply the delicate food processing industry with its large number of concession regulations shall be mentioned here. The food industry not only focuses on the quality of the used raw materials but also on their high-quality processing. In the brewery industry i.e. burster miniature pressure sensors are used to control the exact pressure within bottling plants - directly on the spot and simultaneously with the closure of each bottle. Therefore please allow us the question: Do you like the beer? If yes, this might also be influenced by a miniature pressure sensor in the bottling plant.