The Sensor Profibus Interface has been developed especially for speedy control and real-time tasks and covers a multitude of applications. The excellent measurement accuracy of 0.03 F.S. predestines the module also for high-sophisticated measurement jobs. The potential-free in- and outputs with PLC signal level allow an uncomplicated and easy integration into the given control environment. The Profibus protocol DPV1 permits parameterization, data collection, remote diagnosis and backup function of singular or several modules through a centrally installed control. The setting of the configuration data and the additional functions like arithmetic averaging, filtering, zero balancing, MIN/MAX memory and threshold values can be done via a user friendly configuration software as well as directly via Profibus.

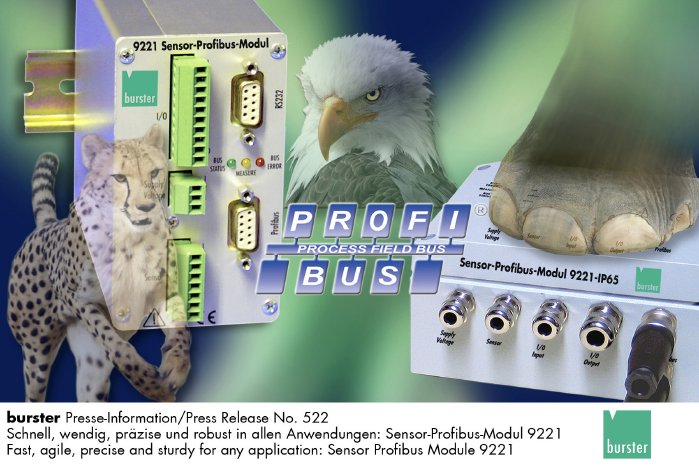

Industry appropriate and functional connection and assembly technologies support the user upon adaptation and integration into the existing mechanical and electrical environs. The module’s DIN rail mounting construction as IP20 version enables a simple installation into switchboard cabinets but it is also available as IP65 version for especially rough surroundings.

Due to its versatility the module suits particularly for the automotive industry where it finds its application fields as i.e. in complex gear and engine test stands or for the weight definition in high-rack facilities. Further it is well-suited for special machinery engineering or the packing industry, manufacturing technology as well as R+D and experimental setups. The detailed application brochure supports the customer with helpful information about the various application fields and methods of solution. The brochure is available free of charge or can be downloaded from the Internet.