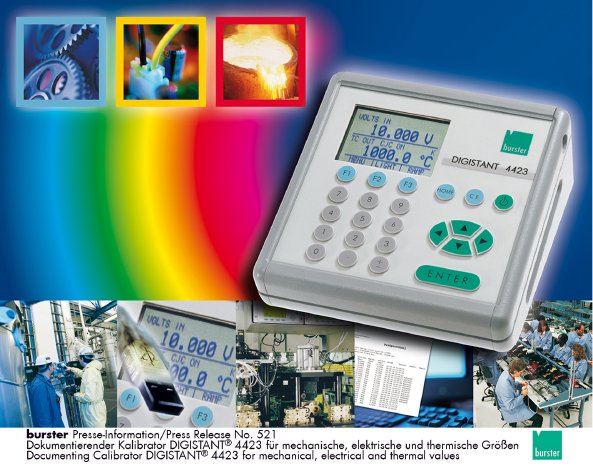

The DIGISTANT® has a robust aluminium console housing for its use on site or in the lab. It offers a wide range of measure and source of 13 types of thermal elements, 13 RTD types, resistance, current, voltage, frequency/impulse, pressure, force, torque and displacement. The user interface is self-explanatory, menu navigation is done via a background lit graphic display. The calibrator works at least 10 hours battery-operated without external power supply but can also operate in buffer mode using the mains adapter provided.

Smart sensor interfaces have been developed to enable the carrying out of force, torque, displacement or pressure calibrations. Thus practically any sensors may be connected to the DIGISTANT®. The smart sensor interfaces hold all special calibration data from the connected sensors in a non-volatile memory. Via the plug and measure connection, the DIGISTANT® recognizes all connected sensors automatically.

The instrument-related software DIGICAL developed especially for the DIGISTANT® supports the complete calibration process from establishing procedures to documenting the results according to DIN ISO 9000. The results can be stored in the equipment for generating documentation and logging then later read out via the integrated USB interface.