Improvements include greater ease of use: both the software for controlling the system and the software for analysing the operating data have been optimised. A data log measures all 19 parameters of the system every two minutes and stores the values for a period of four weeks. Via Modbus, this measuring data can be conveniently accessed using a tablet or laptop. The pre-installed monitoring system ensures operation reliability, for instance, by continuously monitoring the system’s application limits and automatically sending out warnings about potential liquid slugging. A straightforward online interface simplifies programming and system adjustment and conveniently shows current operating and status information directly on the ECOSTAR display or via Wi-Fi on your computer.

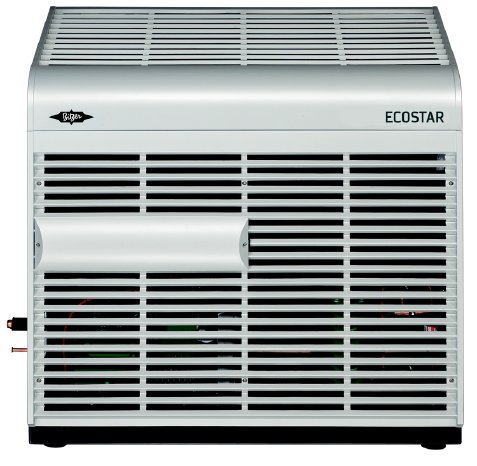

The hardware also offers an extensive range of new features, one of which can be found in the heart of the robust weather protective housing: a NEW ECOLINE VARISPEED reciprocating compressor ensures high cooling capacities. The ECOSTARs are therefore even more versatile and compatible with the full range of conventional refrigerants.

NEW ECOLINE VARISPEED ensures maximum energy efficiency

The NEW ECOLINE VARISPEED also delivers maximum energy efficiency thanks to infinite speed control based on a frequency inverter. The operating display is now larger and supports seven languages, including Russian, Finnish and Turkish. The two biggest ECOSTAR models, 4DES and 4CES, also feature mini-channel condensers on board. This condenser technology allows us to significantly reduce the refrigerant charge. One of the few things that haven’t changed is activation of the BITZER condensing unit: All ECOSTAR components are fully pre-installed and preset.