Since the 1950s, the world’s largest independent manufacturer of refrigeration compressors has been up and running in Brazil, and for more than 20 years in São Paulo. “This is why we know exactly what requirements the climate in South America places on refrigeration compressors. With 42 sites on all continents, we have a suitable solution for all applications. As a global player, BITZER offers all three main technologies in its refrigeration compressors: reciprocating, screw and scroll compressors. Above all, our quality proves its worth in demanding conditions, like those predominating in South America with its moist and warm climate,” said Fernando Bueno, Managing Director of BITZER Brazil.

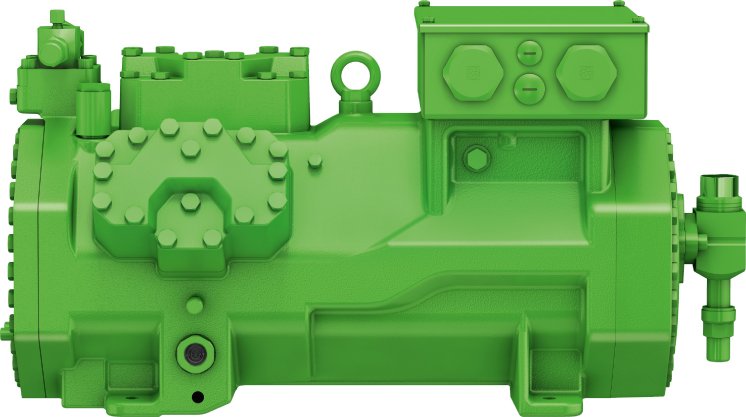

Efficient under high pressure: CO2 reciprocating compressors

One area which BITZER will focus on at the Febrava fair was CO2 reciprocating compressors. The CKH reciprocating compressors for transcritical applications are new, for example. The CKH5 unit on display at the Febrava fair has 6 cylinders, which constitutes a sensible addition to the proven series in the upper capacity range. The five new CKH models offer flow rates from 3.3 to 37.9 m3/h and are impressive on account of their efficiency and compact design. All of the models work in a standard speed range of between 30 and 70 Hz. Due to their innovative cylinder heads, the CKH compressors run more smoothly, with lower pulsation.

BITZER will also be presenting the OCTAGON reciprocating compressors for subcritical and transcritical CO2 applications, which have been specially designed for refrigeration applications and are deployed in places such as supermarkets. In the subcritical range, the OCTAGON models offer a cooling capacity from 1.9 to 82 kW (–35°/–5° C) and improved system efficiency. The additional reinforcement of the housing and drive gear, the specially modified motors for condensing temperatures up to 15 degrees Celsius and the reduced internal flow losses make the OCTAGON compressor especially efficient and robust for subcritical applications. Apart from that, they are very flexible and can be adjusted during operation with a frequency inverter to the capacity requirements concerned. The OCTAGON reciprocating compressors for transcritical applications are also extremely quiet and have low vibration, enabling flow rates from 3.3 to 37.9 m3/h. Moreover, they have a motor cooled by suction gas, which is designed for speed control. Other strengths include the wear-resistant drive gear and cylinder heads with thermally insulated high- and low-pressure chambers. The housings for the OCTAGON compressors for transcritical applications do not need a bottom plate and, on the high-pressure side, can withstand pressures of up to 160 bar and up to 100 bar on the low-pressure side.

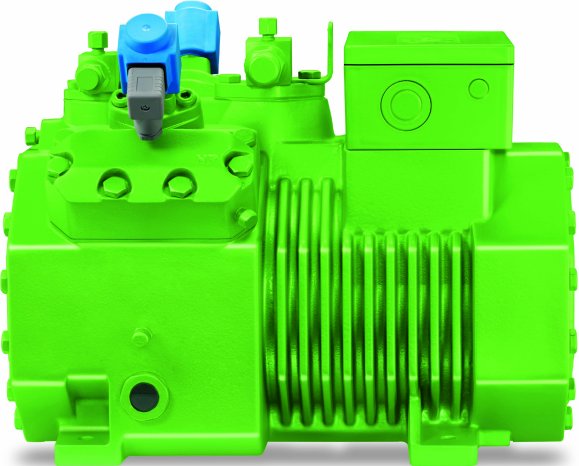

ECOLINE – ideal for all temperatures

Among other things BITZER will be presenting its tried-and-tested ECOLINE series with a flow rate of between 5 and 267 m3/h (60 Hz), which the company also makes in São Paulo. For supermarket applications, the ECOLINE reciprocating compressors can be configured as a cascaded system using R134a (for medium temperature applications) and CO2 (for low temperature applications). They offer operators a lot of flexibility as they can be used with different refrigerants such as R404A, R407A, R507A, R290 and R1270. The fact that they are available in three motor versions is a further strength of the ECOLINE compressors: in motor version 2, they are suitable for use in all medium and low temperature applications, even in tropical ambient temperatures such as those found in Brazil. Motor versions 1 and 3 are designed for heat pumps, for medium temperature applications with 134a refrigerant and for special applications. What is more, BITZER is constantly developing the ECOLINE series and is presenting the new CRII capacity control at the Febrava fair which, thanks to its wide range of control between 10 and 100 percent, enables high flexibility and ideal system efficiency.

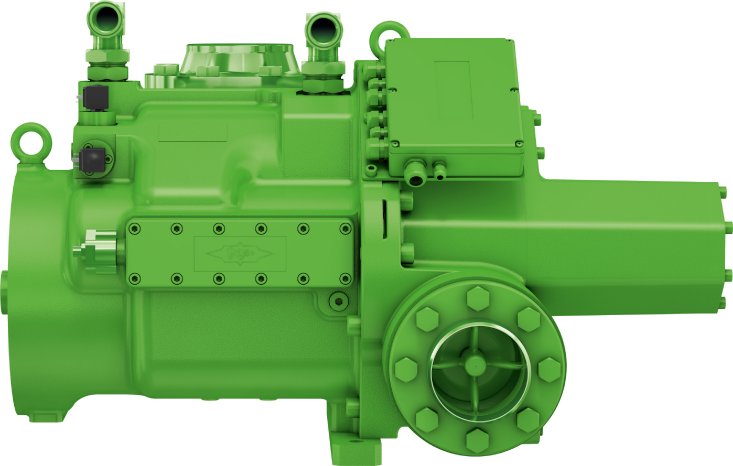

High performance – the screw compressors

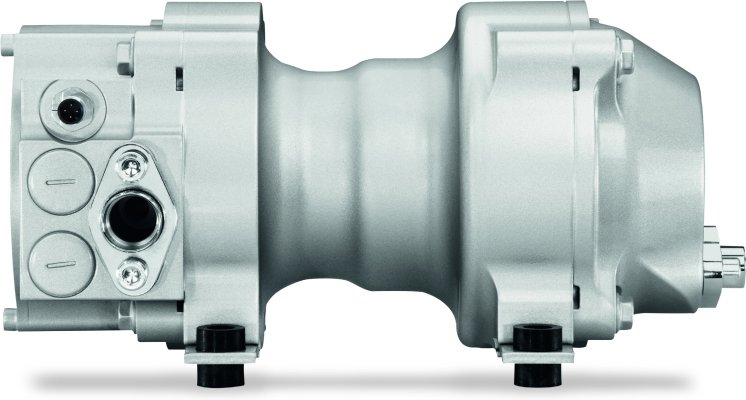

In the area of screw compressor technology, BITZER will be presenting the OS.A95 compressor, which has been optimized in terms of ammonia for industrial and commercial use. With a climate-neutral refrigerant, OS.A95 screw compressors offer another, infinitely controllable area of application. In comparison to the OS.85 compressor model, with the OS.A95, BITZER has almost doubled the flow rate to 1.015 m3/h (at 50 Hz). What can also be seen are the HS screw compressors which have been optimized for parallel operation, with their strengths in terms of high motor efficiency, as well as efficient capacity control and economizer mode. The compact screw compressors in the CSH series are designed for liquid chillers and for heat pumps and have many advantages: the shortest installed length in their class, the optimized oil management system, the additional cooling for extreme operating conditions and the noise insulation. BITZER has further developed the CSH series and now offers a special version for use with the natural refrigerants propane and propylene.

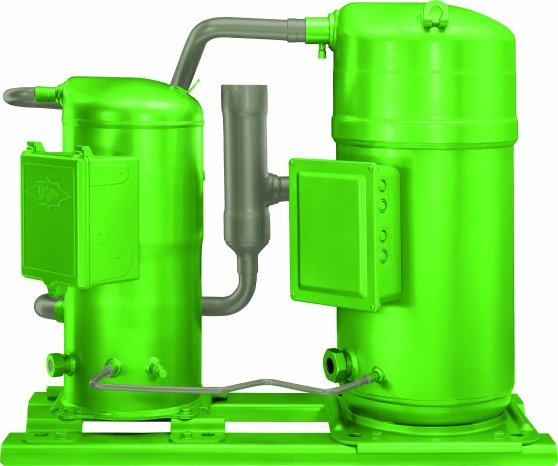

Can be flexibly combined – the scroll compressors

BITZER developed the ORBIT 8 scroll compressors especially for air conditioning applications. They are easy to install, offer high energy efficiency when fully or partially loaded and have the lowest noise emissions in their capacity class. What is more, the energy consumption is extremely low, especially at low condensing temperatures. With the BITZER Advanced Header Technology (BAHT), ORBIT scroll compressors can easily be connected in parallel into groups of two or three units, and that is even possible with differing compressors or if one is frequency-controlled.

Naturally strong – the ammonia compressor packs

For large-scale industrial applications, BITZER has also conceived ammonia compressor packs (ACP), which provide two new developments with an oil separator and a special controller. Up to nine compressors can be wired up to the controller to produce a total capacity of up to 4,500 kW. The ammonia compressor packs are absolutely reliable and are designed for areas where maximum system security is required, such as in food production and in the chemical industry.

Save costs on the road – the mobile solutions

For mobile applications, BITZER designed the two models in the new SPEEDLITE scroll compressor range: the ELV21 and the ELV51 with a capacity from 0.9 kW to 27 kW are designed for use in bus, train and other vehicle applications. Both series are considerably lighter than comparable compressors. This reduces fuel costs, saves the customer money and helps the vehicles’ CO2 emissions fall. BITZER also manufactures the ROADSTAR reciprocating compressors for mobile applications, which are available with 2, 4 or 6 cylinders, in Brazil. Since 2014 the new 4-cylinder unit has also been in production. It has exactly the same capacity as the 6-cylinder unit, but weighs 18 percent less.