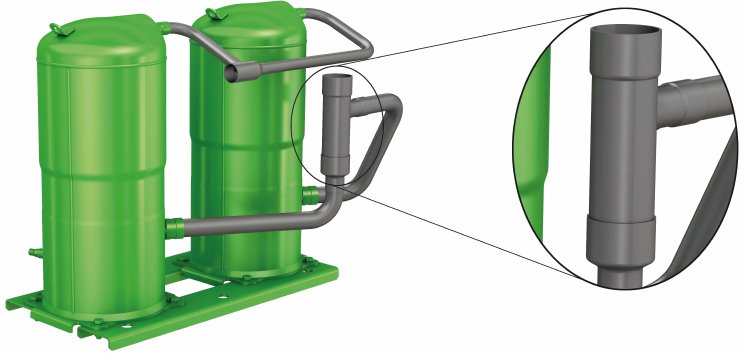

BITZER Advanced Header Technology (BAHT) for scroll compressor tandems and trios makes it easier to use BITZER scroll compressors in parallel circuits for air conditioning and heat pump systems. The newly developed suction gas header with integrated oil distribution plays a key role, specifically directing oil to one of the compressors in the tandem and trio units. The system even works when uneven compressors are combined and allows the frequency of a single compressor to be adjusted. One major benefit is that active oil management with an oil separator is no longer necessary for distributing the oil. Even when a compressor is shut off, oil distribution is maintained in the unit.

Volker Stamer, Director of Stationary Products, explains: ‘BITZER Advanced Header Technology makes a whole host of new capacity combinations possible – occasionally even without active oil equalisation. This is a unique selling point that only BITZER can offer.’

The benefits of BITZER Advanced Header Technology are easy to see: only one suction line is required for many compressor combinations – and without an individual combination of restrictor washers. The system functions with consistent reliability at high and low suction gas volume flows and promotes uneven capacity adjustment through different displacements and compressor housing sizes in one unit.

An overview of the benefits of the new BITZER Advanced Header Technology:

- Only one suction line for many compressor combinations without an individual combination of restrictor washers

- Reliable functioning at high and low suction gas volume flows

- Uneven capacity adjustment through different displacements in the unit

- Different compressor housing sizes (GSD6 and GSD8) in one unit

- Less warehousing, simpler installation and error prevention in the production of multi-compressor units.

The ORBIT 6 scroll compressor range comprises five models with displacements from 20 to 38 cu. m/h at 50 Hz and between 10 and 20 hp. The cooling capacity varies between 27 and 51 kW. ORBIT 6 compressors are ideal for air conditioning systems and heat pumps and boast low sound levels.

The larger ORBIT 8 series has six displacement volumes between 29 and 77 cu. m/h with 15 to 40 hp. The sound level is about 3 dB(A) lower than that of conventional compressors. And the very low oil carry over rate of less than one per cent improves heat transfer properties and increases system efficiency and reliability.