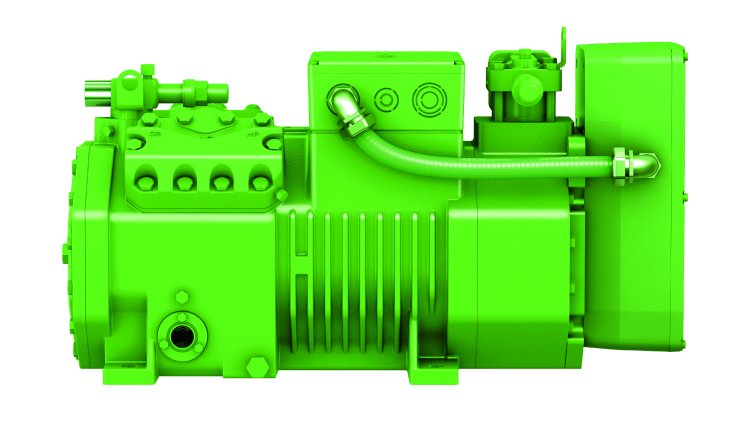

• VARISPEED – the convenient solution: compressor and frequency inverter are a unit

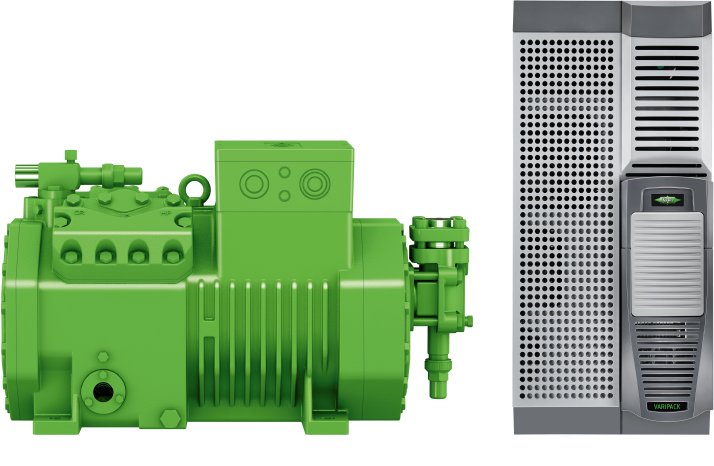

• VARIPACK – the flexible, simple alternative: electronic capacity control in combination with all BITZER reciprocating compressors

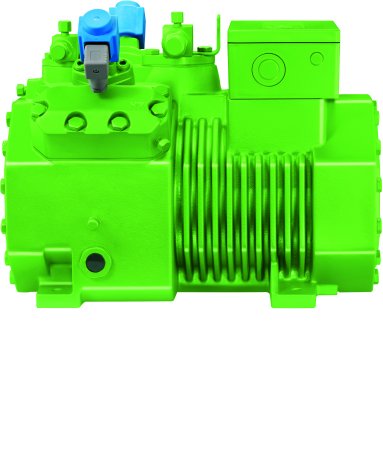

• CRII – the inexpensive solution: mechanical capacity control

Flexibility and an extensive range of applications take priority at BITZER, the compressor specialist, including when it comes to its technologies for capacity control in reciprocating compressors. Refrigeration and air conditioning engineers can choose between the VARISPEED compressor series with integrated frequency inverter, the external VARIPACK frequency inverter and speed control provided by the CRII mechanical capacity control. The different concepts offer individual benefits, increase energy efficiency and reduce life cycle costs.

Each application is unique, which is why BITZER refrigeration compressors, like the capacity controls, are specially tailored for specific requirements. With the CRII capacity control, the intelligent VARIPACK frequency inverters and the VARISPEED compressors, BITZER can offer several options – users can select the appropriate technology for their application. Both mechanical capacity control and capacity control based on speed adjustment have their specific benefits under the prevailing operating conditions.

Frequency inverters fundamentally have a soft start characteristic combined with low starting currents when starting the compressor. What’s more, they don’t work in stages and are therefore the optimal solution in terms of control, as the desired evaporation temperature can be selected with the utmost precision. If part-load operation is the primary mode, systems with an electronic frequency inverter are more efficient than mechanical systems due to limited switch cycles. A disadvantage compared to mechanical capacity control: the investment costs for electronic frequency inverters are somewhat higher.

CRII: the inexpensive path to optimised capacity control

The CRII mechanical capacity control, which BITZER developed from its predecessor, the CR capacity control, is the entry-level model and an inexpensive variant. Now it boasts much fewer control deviations and a much larger range of control. Compared with compressors operated with frequency inverters, the CRII achieves somewhat lower efficiency levels in the lower part-load range and, despite the high switching frequency, poor control quality. However, this is of little importance when it comes to systems with several compressors and large-volume cooling positions. The modulation range for two, four and six-cylinder compressors is between 10 and 100 per cent and, for eight-cylinder compressors, between 50 and 100 per cent. BITZER will be presenting its mechanical capacity control, including for transcritical CO2 applications, for the first time at the Chillventa 2016 trade fair. One of the benefits of the CRII capacity control: electromagnetic compatibility is not an issue and the mechanical solution has no influence on network quality in buildings.

VARIPACK: flexible and simple

In combination with BITZER reciprocating compressors, VARIPACK frequency inverters are the flexible solution that can be used in just about any application. Specially developed by BITZER for use in refrigeration and for operation with refrigeration compressors, the external frequency inverters are particularly suitable for simple and reliable capacity control. BITZER software enables application-specific selection of the frequency inverter, whilst the BEST (BITZER Electronics Service Tool) software promotes simple operation and monitoring. Stored databases allow for complete, straightforward configuration of each compressor simply by selecting the compressor model and refrigerant. The new products offer reliability and convenience due to optimal coordination with BITZER refrigeration compressors. With its modular design, the VARIPACK series achieves a high degree of flexibility and opens up a wide spectrum of variants for a large range of applications in supermarkets, hotels, restaurants and food production and processing centres. The series is suitable for refrigeration, air conditioning and heat pumps and can be integrated into both systems with single compressors and compound systems.

VARISPEED: the compact solution

The VARISPEED product series is the most simple frequency inverter solution for small and medium-sized reciprocating compressors, as it represents a compact, reliable and convenient option: the suction gas-cooled frequency inverter and the compressor form a compact unit and all the components are factory mounted, making separate installation a thing of the past. The components are fully wired, optimised for EMC – refrigeration and air conditioning engineers don’t have to put any thought into mounting or the frequency inverter and motor wiring. Due to their special design, VARISPEED compressors can be operated at a frequency of up to 87 Hz. However, the VARISPEED series is not available for all BITZER ECOLINE compressors and the frequency inverters have limitations when it comes to the maximum evaporation and suction gas temperature. VARISPEED compressors are therefore not the first choice when it comes to many heat pump applications.

Overview of images

Images may only be used for editorial purposes. This usage is free of charge if "Photo: BITZER" is given as the source and a complimentary copy is forwarded to us. Changes to the images – apart from cropping to the main motif – are not permitted.