NEW ECOLINE RECIPROCATING COMPRESSORS

The NEW ECOLINE series offers both increased efficiency and wider application limits yet can still fit into existing systems as a replacement. BITZER has succeeded in improving the entire range’s efficiency, especially in low condensing temp applications. In addition to R134a, they can now be used with refrigerants such as R404A, R407A, R407C, R407F and R507A. With the new series, BITZER is transferring all the advantages of the proven ECOLINE series to an even broader range of applications in order to provide customers with significant added value.

NEW ECOLINE VARISPEED COMPRESSORS

The NEW ECOLINE VARISPEED semi-hermetic reciprocating compressor features an integrated, suction gas-cooled frequency inverter that can be infinitely adjusted, making it possible to reduce fluctuations in suction pressure and cycling rates and thus lower energy costs. Using suction gas to cool the operating elements of the frequency inverter ensures that electrical components remain at optimum temperature without the need for external fans.

CSV SCREW COMPRESSORS WITH INTERGRATED VFDs

The CSV series of intelligent, networkable compact screw compressors features unrivalled efficiency thanks to their ultramodern technology. The fully integrated frequency inverter is cooled by refrigerant and includes infinitely variable speed control to ensure the right temperature profile. Proactive monitoring of the application limits guarantees the utmost in operational reliability. While older systems simply switch off when a deviation is detected, CSV series compressors send an advance warning to the overriding system controller, allowing you to take preemptive action.

All CSV series compressors are fitted with pressure and temperature sensors, oil heater control and power supply monitoring. All components are functionally pre-wired and tested, so installation is remarkably quick. Our CSV series compressors are also easy to use in combination with CSH and CSW series compressors for maximum efficiency with no hassle. Further benefits of the CSV series include broad operating parameters spanning the entire speed range, compact design, soft start function and an automatic compressor system check every time the compressor is switched on.

ORBIT 6 SERIES SCROLL COMPRESSORS FOR A/C & HEAT PUMPS

With cooling capacities ranging from 10 to 20 tons, BITZER’s new R410A ORBIT 6 Series Scroll Compressors offer a high degree of isentropic efficiency, a wide application range and impressively low sound levels. At standard rating points, ORBIT 6 models are 2-5% more efficient than competitor models, have an IPLV up to 5% higher, and are 2-4 dB(A) quieter. Max operating amperages are 7-12% lower. ORBIT 6 models are available in both even and uneven tandem and trio configurations.

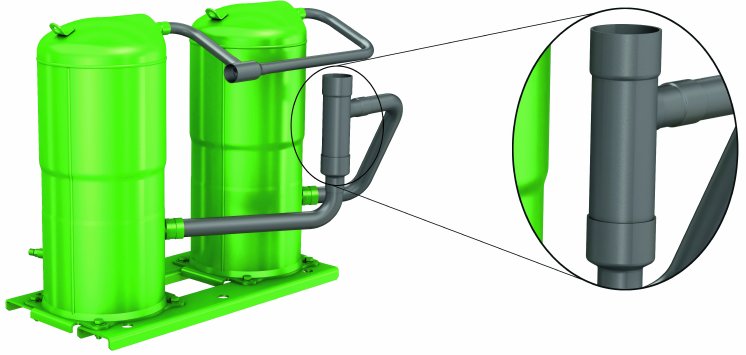

BITZER ADVANCED HEADER TECHNOLOGY FOR SCROLL TANDEMS AND TRIOS

BITZER‘s new patent pending Advanced Header Technology for uneven Scroll compressor tandems and trios provides game-changing opportunities for OEMs designing their next generation systems. Taking advantage of the unique design characteristics of the ORBIT series compressors, including an isolated oil sump design and good miscible PVE oil, BITZER’s ORBIT series has exceptionally low oil carry-over rates. The Advanced Header Technology then operates by ensuring that small differences in pressure drop in header tubing does not impact oil balance between compressors in low mass-flow situations like those found in many air-to-water heat-pumps.

The result is a powerful combination of benefits for OEMS. A single header package can be used for up to 20 different capacity combinations resulting in lower inventory costs. Uneven tandems can be selected to maximize full load, part-load or other customer requirements. Addtionally, BITZER’s advanced header technology does not require internal restrictor washers that can be difficult to manage on the production floor and, therefore, work well with many OEMs’ lean production systems.