• Optimized for high switching frequencies

• Improved system efficiency

• CAREL and ELREHA are already offering controllers

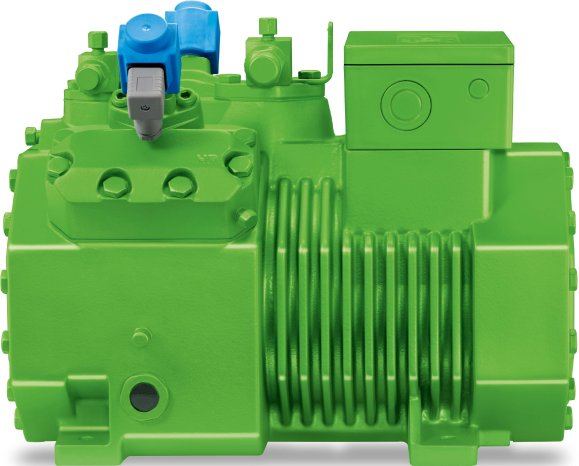

Sindelfingen, 29.07.2014. Compressor specialist BITZER presents a new capacity control system for its ECOLINE reciprocating compressors.

BITZER has optimized its tried-and-tested CR capacity control system by adding blocked suction and offers high flexibility and exceptional reliability with its new CRII system. The heart of the CRII system is the new hollow control piston. This new system promotes higher switching frequency, protects the environment and reduces costs.

Depending on the operating ¬conditions and refrigerant, a special control algorithm allows compressors to be infinitely adjusted: with the CRII, BITZER has achieved an exceptionally wide range of control between 10 and 100% for four and six-cylinder compressors. The increased switching frequency, however, ensures smaller fluctuations in controlled value, temperature and pressure and, in combination with the expanded range of control, optimizes system efficiency. As a result, tandem compressors can even be reduced to 5%.

The CRII system is available for the ECOLINE series with a capacity range of four to eight cylinders. All the cylinder heads in the ECOLINE compressors 4FES-3(Y) to 6FE-50(Y), as well as the two external cylinder banks in the compressors 8GE-50(Y) to 8FE-70(Y), can be retrofitted with CRII. Compressors are also available with the CRII cylinder heads premounted.

In mid-February, CAREL – an international manufacturer and a specialist in electronic control solutions and components for refrigeration, air conditioning, heating and ventilation technology – presented the pRack pR300, a high-tech compounding system controller for the innovative CRII system, at the trade fair EuroShop 2014 in Düsseldorf. Simply pick out the compressor model using the built-in assistant of the pRack pR300 and the system automatically selects the right settings for a smooth system start-up and the right system management based on the specifications approved by BITZER.

ELREHA has also designed a new controller, the MSR eco 3130, for use in compounding systems with the CRII system from BITZER.

Wurm has been involved in BITZER’s CRII project from the outset and it supports the CRII system with the standard main modules for compounding systems from its highly successful Frigolink range. The additional ASV101 driver module is controlled by the compressor module and ensures that the capacity of the compressor is controlled on an almost continual basis. The ASV101 can easily be parameterized based on the Frigolink main module by selecting an operation mode.

Volker Stamer, BITZER Director of Sales for Stationary Products, notes: “With the CRII system, we are offering our customers a whole new level of flexibility and supporting customization to suit all possible ECOLINE operating conditions. This increases system efficiency whilst protecting the environment.”