‘China Refrigeration is one of the central trade fairs for the refrigeration and air conditioning sector – and the Chinese market is one of the most important for us,’ says BITZER Chief Sales and Marketing Officer Helmut Meyer. ‘This is why we are clearly focusing on China Refrigeration in 2015, and we look forward to being there again in the Chinese year of the sheep. We are expecting a tremendous trade fair with plenty of visitors and interesting discussions.’

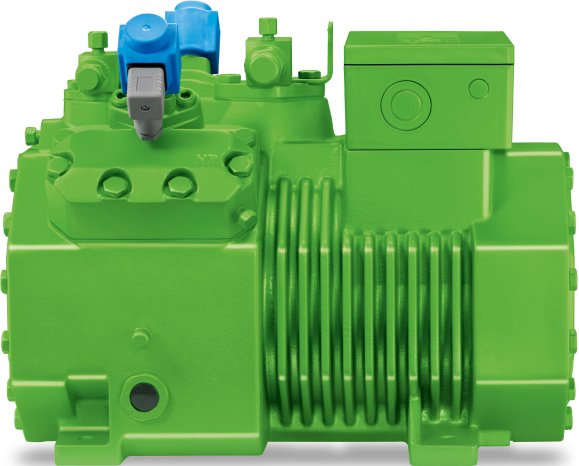

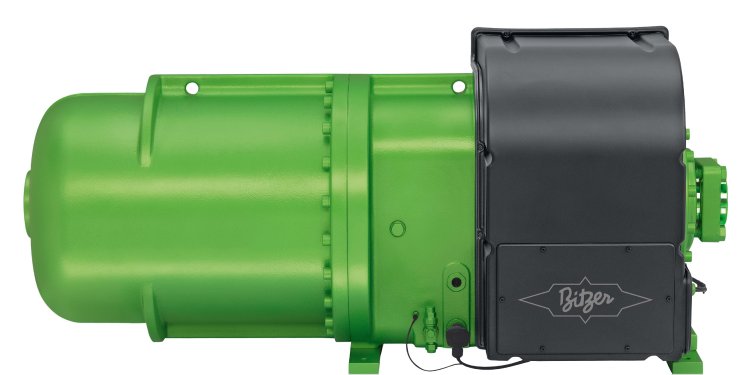

Flexible and friendly to the environment – the BITZER reciprocating compressors

Reciprocating compressors belong to BITZER’s most important product areas and, in tandem versions, some can offer flow rates of up to about 300 m3/h (50 Hz). One of the BITZER highlights for China Refrigeration 2015 is the family of ECOLINE reciprocating compressors designed for supermarket applications, air conditioning systems and heat pumps as well as the compatible CRII capacity control system. This new control system allows cylinders to be switched off at optimal times, a wide range of control between 10 and 100 per cent and high reliability. Other advantages of the CRII system include being able to lower operating costs and protect the environment thanks to the high switching frequency. In the VARISPEED version, the ECOLINE has an ideal, factory-integrated frequency inverter cooled by the suction gas, which permits the cooling capacity to be smoothly adjusted. This lowers energy costs as the variations in suction pressure are reduced, as is the frequency of switching. BITZER will also be presenting new CO2 reciprocating compressors at the trade fair. These are available for subcritical and transcritical applications in various series and flow rates, permitting flexible choices for all operating conditions.

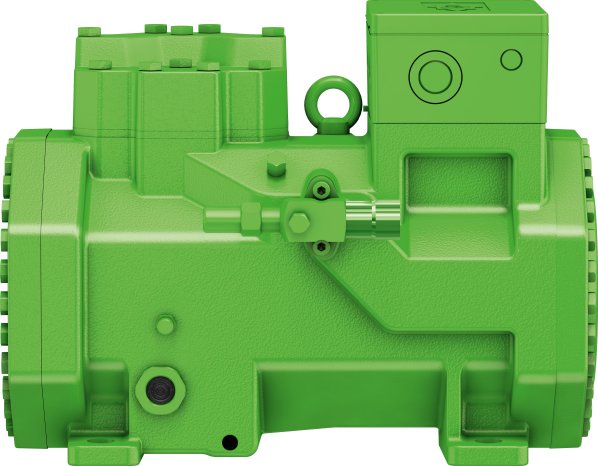

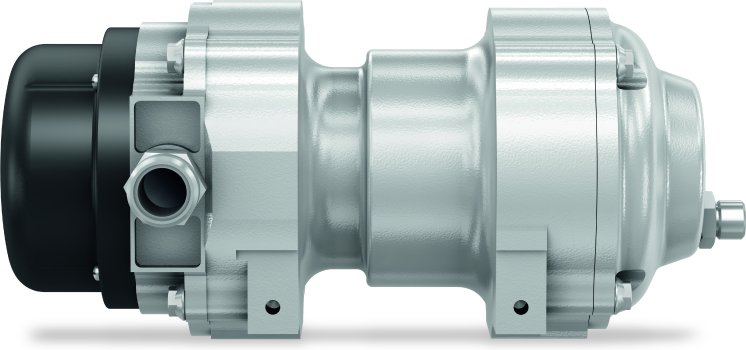

ROADSTAR reciprocating compressors for mobile applications

BITZER has further refined its range of ROADSTAR reciprocating compressors for mobile air conditioning applications. The more powerful drive increases reliability and prolongs the lifetime of the units, even under the toughest conditions. The ROADSTAR 4GFC has been specially designed for operation under demanding conditions when used in vehicles. As a four-cylinder model, the 4GFC aluminium compressor offers a light and compact alternative to the six-cylinder version, making it particularly suitable for articulated and double-decker buses as well as for use in hot countries. The ROADSTAR 4GFC offers the greatest performance in its class relative to size. It is 18 per cent lighter than the comparable six-cylinder compressor, while offering its high cooling capacity with the dimensions of a four-cylinder unit.

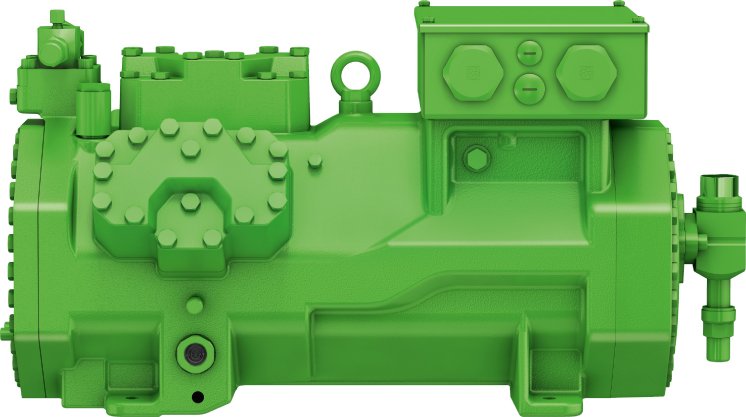

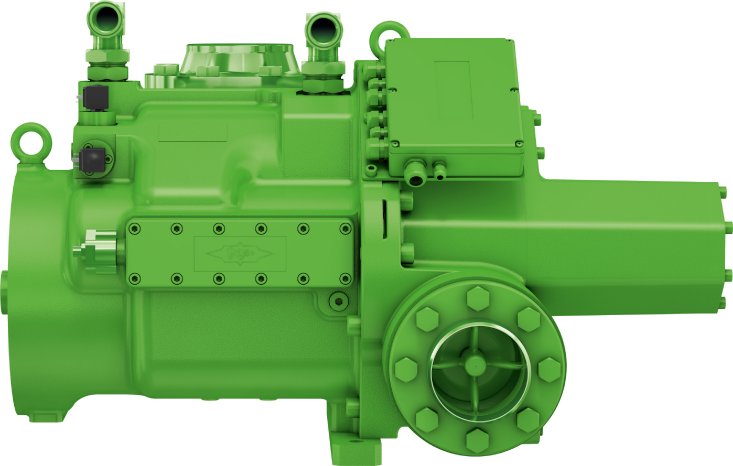

High performance and innovative – BITZER screw compressors

BITZER screw compressors also support a variety of uses, particularly in large commercial and industrial applications. In parallel systems, they can offer flow rates of up to 3,000 m3/h (50 Hz). The CSVW2 compact screw compressor is a new unit for water-cooled liquid chillers, with its innovative drive technology, using a permanent magnet motor. This allows the CSVW2 to achieve high efficiency levels, especially at lower speeds and capacity ranges. With its open OS.A95 screw compressors, BITZER can offer highly efficient performance, while protecting the environment at the same time. The OS.A95 is designed to use ammonia as a refrigerant. Given the worldwide trend to refrigerants with low global warming potential, this will presumably gain even more significance in the future. For the flow rate of 1,015 m3/h (at 50 Hz), which has almost doubled in comparison to the OS.A85, BITZER has developed specially matched oil separators. BITZER is also showing its screw compressors from the HSN series. These are designed for use in parallel and offer a high system performance as well as low energy consumption when fully or partially loaded. Using slider control, users can choose between controlling capacity smoothly or in steps.

VSK compact screw compressors for the air conditioning of railway carriages

In Shanghai, BITZER is also showing its hermetically sealed VSK compact screw compressors for the lower capacity range. Above all, the VSK series was developed for air conditioning units, liquid chillers and for the air conditioning of railway carriages. Due to its space-saving design, its low weight and its integrated oil storage and and separation system, it is easy to install.

Reliable and suitable for use in combinations – BITZER scroll compressors

When used in trio scroll compressor assemblies, the reliable BITZER scroll compressors can achieve flow rates of up to 220 m3/h. The ORBIT 6 and ORBIT 8 are designed for use in air conditioning systems and heat pumps. They are very efficient, whether fully or partially loaded and, with a flow rate from 20 to 77 m3/h, they are extremely flexible. With the BITZER Advanced Header Technology (BAHT) for scroll compressor tandems and trios, even and uneven scroll compressor sizes can be connected together in air conditioning and heat pump systems, even if one compressor is frequency controlled.

For air conditioning in buses, trains and metro applications, at China Refrigeration 2015, BITZER is presenting the new, horizontal, semi-hermetic SPEEDLITE ELV scroll compressors with frequency inverters cooled by suction gas. The three compressors in the two sizes of housing provide a cooling capacity of 0.9 kW to 5.5 kW, 0.9 kW to 7.5 kW and, in the SPEEDLITE ELV51, up to 27 kW with R134a at SST = + 5°C and SDT = 50°C. During the development of this compressor family, the main focus was on the scroll spirals, the electric motor and the frequency inverter, which have been brought together to form a new system. This enables the components to work most efficiently together and ensures high reliability.