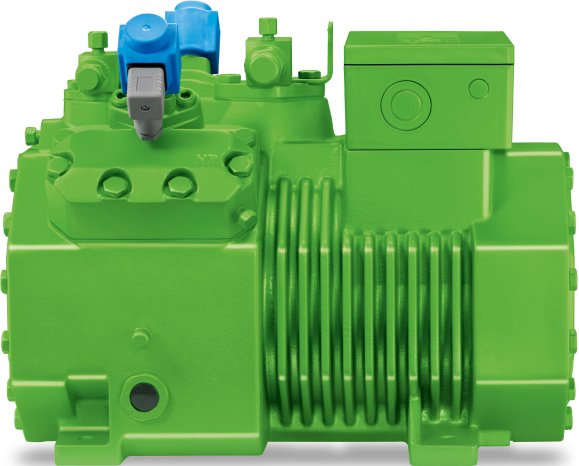

One of the many new products the compressor specialist will be showcasing in Nuremberg is the further optimized CRII capacity control. The system delivers virtually infinitely adjustable capacity control for the ECOLINE reciprocating compressors with four, six and – now for the first time – two cylinders.

CRII: low operating costs thanks to efficient compressor control

Depending on the operating conditions and refrigerant, a special control algorithm allows compressors to be infinitely adjusted. With the CRII, BITZER has achieved an exceptionally wide range of control between 10% and 100% for two-, four- and six-cylinder compressors. The increased switching frequency, however, ensures smaller fluctuations in controlled value, temperature as well as pressure and, in combination with the expanded range of control, optimizes system efficiency.

Volker Stamer, BITZER Director of Sales for Stationary Products, explains: “With the CRII system, we are offering our customers a whole new level of flexibility and supporting customization to suit all possible ECOLINE compressor operating conditions. This increases system efficiency whilst protecting the environment.”

Further steps in efficiently creating refrigeration with CO2 compressors

BITZER is also always expanding its range of CO2 compressors. With the introduction of the 4PTC-6K model for lower displacements and the 4DTC-25K and 4CTC-30K models for higher displacements, the series for transcritical compressors now ranges from 4.3 to 25.6 cubic meters of displacement per hour at 50 Hz. Chillventa trade fair visitors can look forward to an expanded product range and a new CO2 series at the BITZER stand.

World premiere in screw compressors

For the first time, BITZER is presenting a new, eye-catching open-drive screw compressor in the OS series to the public. The model is based on the tried-and-tested construction of the OS series and, for now, is designed for use with NH3 (ammonia) in medium and low temperature applications. BITZER therefore offers the refrigeration and air conditioning industry a compressor solution tailored to meet the requirements of industrial applications. Further models for industrial applications are already in development.

Greater cooling capacity with CSVH3 compact screw compressors

The CSVH3 series is a new development in the field of regulated speed-regulated compact screw compressors. BITZER has added two significantly more powerful larger models to its existing CSVH series. The CSVH37 compact screw compressor has a cooling capacity of 550 kW (+5/50°C) with a displacement of up to 960 m3/h. The larger CSVH38 possesses an impressive cooling capacity of 660 kW (+5/50°C) with a displacement of up to 1,156 m3/h. BITZER has developed a new housing size to achieve this level of performance. The series is based on the proven engineering and electronics of the CSVH2 series and has a very wide range of applications, from air cooled liquid chillers to heat pumps.

The CSVW2 is also a compact screw compressor, specially designed for liquid chillers with a low condensing temperature. Its engineering is based on the tried-and-tested CSVH2 compact screw compressor and combines proven strengths with new capabilities at low load conditions. In order to achieve a high coefficient of performance (COP) for this type of application, and thus a good ESEER, BITZER has integrated a permanent magnet motor. The innovative drive technology is beneficial particularly in liquid chillers with a water cooled condenser. The internal volume ratio (Vi) of the compressor was also adjusted to allow the CSVW2 series to achieve much better efficiency in the lower speed and load range than the CSVH series. BITZER modified the frequency inverter accordingly.

Scroll compressors optimally combined

In the scroll compressor segment, the new BITZER Advanced Header Technology (BAHT) for compressor tandems and trios is pioneering in the design of air conditioning and heat pump systems.

The newly developed suction gas header plays a key role, as it specifically directs oil to one of the compressors and then, inside the compressor tandem or trio, distributes it evenly among the other compressors. The system even works when uneven compressors are combined and allows the frequency of a single compressor to be adjusted in the unit. The unit does not require active oil management with an oil separator or a lead compressor into which the oil can flow back. Even when one or two compressors are shut off, oil distribution is maintained.

BITZER Advanced Header Technology offers the following benefits:

• Only one suction line for many compressor combinations without an individual combination of restrictor washers

• Reliable functioning at high and low suction gas volume flows

• Uneven capacity adjustment through different displacements in the unit

• Different compressor housing sizes (GSD6 and GSD8) can be combined in one unit

• Less warehousing, simpler installation and error prevention in the production of multi-compressor units

The lower oil carry over rate of the ORBIT scroll compressors and the new suction gas header promote longer operation with equalized oil levels in the compressors, even in demanding conditions, including the integration of reversible heat pumps and iced evaporators. The oil needs to be able to return to the suction line.

Well equipped for the future: ECOSTAR and LHE condensing units

The new air cooled LHE condensing units are worth taking a look at, as they already fulfill the European Union’s ErP Directive (Energy-related Products Directive) – the so-called Ecodesign Directive. The Association of European Refrigeration Compressor Manufacturers (ASERCOM) confirms the high standards of the LHE condensing units. The first LHE products have already received the newly created ASERCOM certification for condensing units. Like the optimized ECOSTAR condensing units, they too represent another highlight at the BITZER trade fair stand.

Volker Stamer, BITZER Director of Sales for Stationary Products, notes: “We are proud to be able to showcase our latest innovations at Chillventa 2014 and look forward to chatting with visitors. It’s well worth a visit, as we have a whole lot more in store.”