Compressor specialist BITZER works towards a climate-friendly future, consequently always keeping the following key elements in mind: natural refrigerants, energy efficiency and user-friendliness. At the Russian trade fair Climate World, BITZER CIS will be exhibiting some of the company’s important screw and scroll innovations.

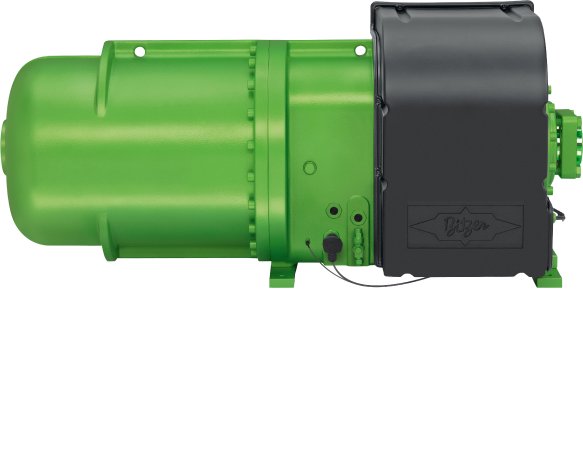

Efficient and flexible compact screw compressors: the CSVH2 series

The CSVH2 series is a unique development in the field of compact screw compressors, especially designed for speed control and optimised for use in air-cooled liquid chillers and heat pumps. The series is provided with an integrated frequency inverter which controls the motor speed – enabling infinite capacity control for users and an optimal energy use for any application. Like the bigger CSVH3, the CSVH2 monitors its own application limits. If a value exceeds the set parameters, the BITZER compressor gives a warning and the option to adjust the performance and operating parameters. And then, if the overstressing continues, the control switches the compressor off autonomously.

The compressors are very reliable, lightweight and based on proven engineering as well as on innovative motor technology and electronics. They are smart, network-compatible and already comply with future standards in full- and part-load operation. The integrated refrigerant-cooled frequency inverter ensures stable operation and a precise temperature profile for the medium to be cooled. With the CSVH2 and the CSVH3 series, BITZER offers the complete service range up to 1,156 m3/h displacement even in the field of highly efficient speed controlled compressors with integrated frequency inverters. The CSVH2 compact screw compressor series is approved for refrigerants with low global warming potential like HFO/HFO mixes. BITZER’s entire CS and CSV series have been approved for the R1234yf, R1234ze(E), R513A and R450A refrigerants since the beginning of 2016.

ORBIT scroll compressors – flexible and efficient team players

BITZER developed its ORBIT 6 and 8 scroll compressors especially for air-conditioning and heat pump applications. They are easy to install, offer high energy efficiency when fully or partially loaded and have the lowest noise emissions in their capacity class. Furthermore, the ORBIT models operate at peak efficiency despite demanding conditions, helping to reduce system footprints through their compact size and unique compound solutions. Users can choose from two proven compressor families: ORBIT 6 and ORBIT 8. They are extremely compact and boast low energy consumption and low noise operation. In addition, they are variable-speed-ready (ORBIT 6 and 8: 35 to 75 Hz). The extended frequency ranges offer major benefits: users can precisely tailor the speed and cooling capacity of ORBIT scroll compressors to match actual load requirements for outstanding energy efficiency in both full- and part-load operation. This leads to especially high EER, ESEER/IPLV and SCOP values and thus lowers operating costs. All BITZER ORBIT 6 as well as ORBIT 8 models are interchangeable within their own respective series, allowing system designers and manufacturers to simplify development work by using existing frameworks, piping layouts and manufacturing processes – leading to reduced complexity and more flexibility. Moreover, the ORBIT 6 and 8 scroll compressors are designed to work with A1 refrigerants and are optimised for R410A.

Even when it comes to displacement, the ORBIT 6 and 8 series offer exceptional flexibility with capacities from 20 to 77 m3/h at 50 Hz. Thanks to their high evaporation temperature limits, the compressors are also suitable for data centres. They can be combined very easily with the proven BITZER Advanced Header Technology (BAHT) for tandem and trio compound assemblies. ‘BAHT even works with different capacities and without active oil equalisation – in many cases even if a compressor is frequency-regulated,’ adds Rainer Große-Kracht, Chief Technology Officer at BITZER.

Overview of images

Images may only be used for editorial purposes. They can be used free of charge if the source is given – ‘Photo: BITZER’ – and a free copy of the publication is sent to us. Images may not be modified or altered, except to crop out the background surrounding the main subject.