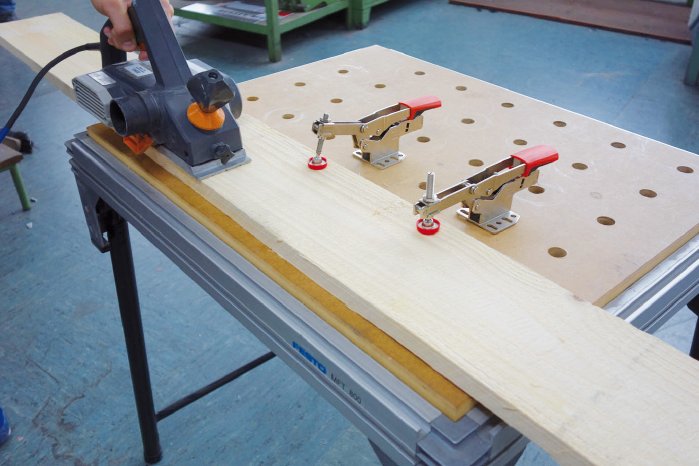

The new toggle clamp adapter STC-SET-T20 can be used together with the larger versions of BESSEY toggle clamps that have horizontal base plates and a borehole in the centre of the base. These include the horizontal toggle clamps STC-HH50 and STC-HH70, the vertical toggle clamp STC-VH50 and the push/pull clamp STC-IHH25.

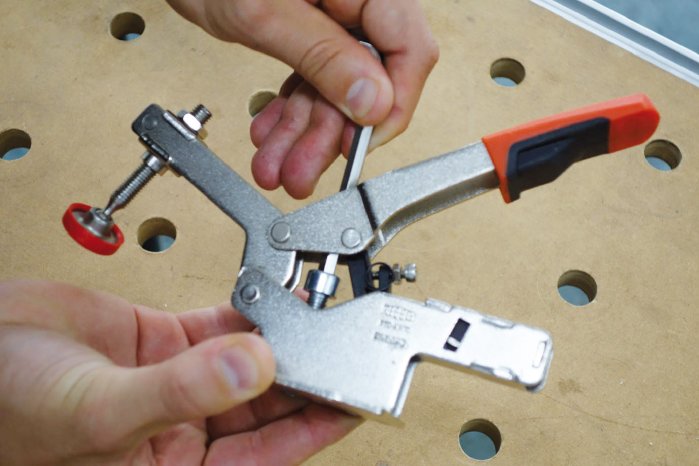

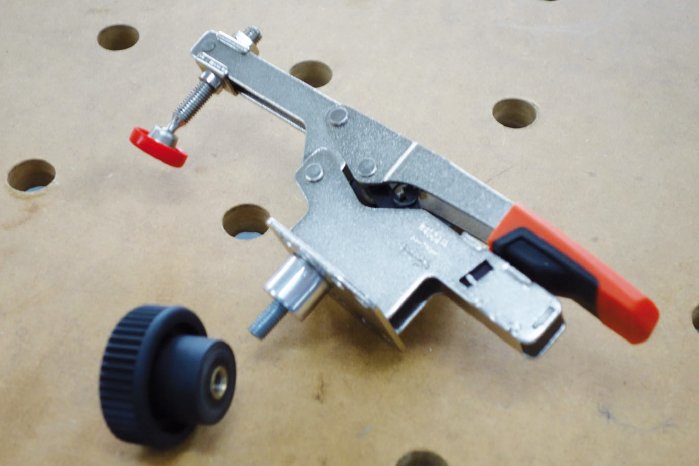

The three-part accessory can be assembled in a few simple steps: First, the clamp lever is opened to 45° in order to insert the screw through the lever mechanism and the base plate. The Allen key is then positioned and the locking post is threaded in from below; hand tighten and then complete tightening using the Allen key. With this adapter, the clamp can be used on multifunction tables with a 20 mm hole diameter and a surface thickness between 19 mm (minimum) and 25 mm (maximum). Finally, the toggle clamp is secured from below using the locking knob to firmly attach to the table.

With this clever accessory you are now able to take advantage of the numerous benefits of BESSEY toggle clamps on multifunction tables. For example, you now have the ability to clamp different workpiece thicknesses without adjusting the clamping screw manually and with practically the same clamping force. What’s more, you can do this up to five times faster than with conventional clamps. This time saving is made possible by the infinitely variable clamping width of up to 35 mm on horizontal and vertical clamps and up to 13 mm on a push/pull clamp. But that’s not all. The clamping force of BESSEY toggle clamps can be adjusted to a maximum force of 2500 N without the use of tools to suit the workpiece at hand. When the clamp is used in conjunction with a flexible pressure plate with a removable protective cap, fragile materials such as veneered or lacquered surfaces can be clamped in a gentle manner.

The toggle clamp adapter STC-SET-T20 costs EUR 10 (MSRP excl. VAT). All BESSEY toggle clamps that are suitable for use on multifunction tables can also be purchased together with an adapter as a set. The horizontal clamp set STC-HH50-T20 and the vertical clamp set STC-VH50-T20 cost EUR 34 each, the horizontal clamp set STC-HH70-T20 costs EUR 34.70 and the push/pull clamp set STC-IHH25-T20 costs EUR 35.30 (all prices MSRP excl. VAT).