Products from B&R easily withstand all environmental influences

Manufacturers use B&R products in machines and systems all over the world, including in mobile machines and offshore equipment. These applications subject them to extreme temperatures, shock, vibration, sea air and radiation from radio and radar equipment. Even under these adverse conditions, B&R products perform with utmost reliability for many years.

B&R lab tests effects of environment on devices ...

In the environmental testing laboratory, technicians are able to simulate the various environmental conditions the devices will later be confronted with in the field. Multiple climate-controlled chambers establish temperatures ranging from -40°C to +85°C and relative humidities ranging from 10 to 98 percent. Tests are designed to ensure that the products are able to handle all types of climate-related strain during operation and that frequent temperature fluctuations do not cause them to age prematurely. Shock and vibration tests simulate intense mechanical strain.

A salt spray test exposes the products to a saline fog with 5% salt content to test their resistance to corrosion. A high voltage test applies a voltage of 6.5 kV to the products to ensure that no arc-overs occur between circuit board tracks, and the bleeder resistance is tested with 1,500 V. In a shielded enclosure, immunity tests are performed with discharges of up to 30 kV, bursts of up to 5.5 kV and surges up to 5 kV to determine the electromagnetic compatibility of the devices.

... and effects of devices on their environment

Conversely, there are also very strict regulations regarding the effects that devices are permitted to have on the environment in which they operate. For purely electrical equipment, as is the case with B&R, these effects include acoustic, thermal and radio emissions as well as the introduction of voltage spikes and harmonics back into the electricity grid. These factors are also tested in the shielded enclosure. In a semi-anechoic chamber more than nine meters long, five meters wide and five and a half meters high, electromagnetic emissions in the gigahertz range are measured over a distance of three meters.

B&R's in-house laboratory increases product quality

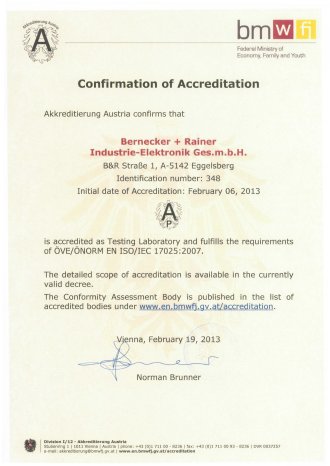

Since receiving accreditation from the Austrian Federal Ministry of Economy, Family and Youth in February 2013, B&R's environmental testing laboratory has now achieved the status of an accredited testing facility. "Having our own accredited environmental testing laboratory gives us a great deal of autonomy," says Franz Stadler, head of B&R's environmental testing laboratory. "We can perform tests more frequently during development and thus continuously improve the quality of our products."