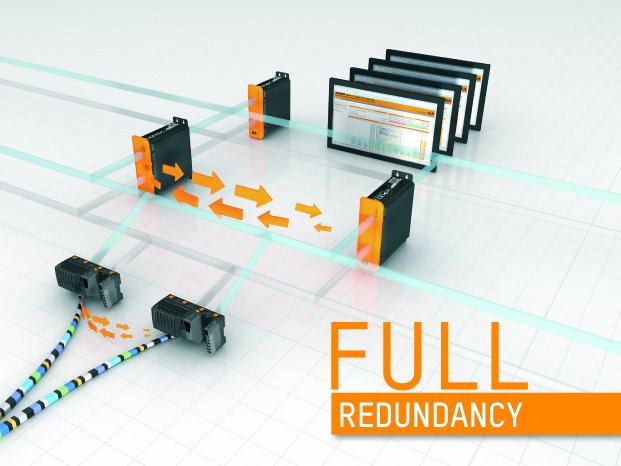

Redundancy with standard hardware

For some time, B&R has provided the option of using standard components from the X20 control system to establish controller redundancy. This eliminates the need for costly specialized hardware. Standard control computers from B&R's Automation PC series are also well-suited for constructing redundant server systems. Since the servers hold not only historical archives but also critical applications such as the real-time database and the alarm and trend servers, their failure would have severe consequences.

Changeover within a few milliseconds

The primary and secondary controllers or servers exchange data constantly via a redundancy link. Should the primary unit fail, the powerful real-time Ethernet POWERLINK provides a fast and seamless transition to the secondary controller within a few milliseconds.

APROL allows operator stations, which are typically redundant, to be designed using standard components. With POWERLINK, B&R offers flexible options for redundant fieldbus systems. APROL makes it possible to implement fieldbus redundancy using third-party systems. Configuration options can be used to enable or disable redundancy.