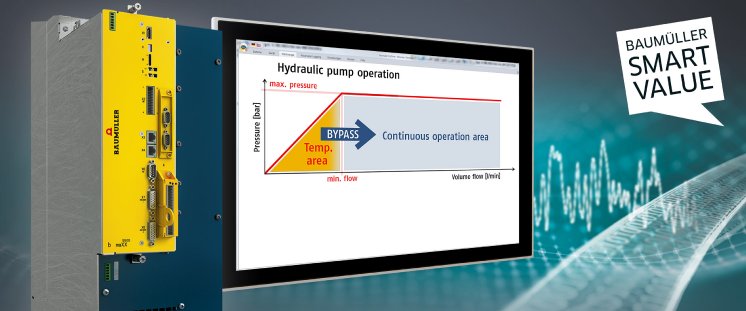

The current thermal pump utilization is determined using a dynamic calculation model and monitored in the monitoring. The utilization is calculated via speed, pressure and, if available, via the oil tank temperature directly in the servo converter. The calculation takes place with a very short cycle time of 1 ms. If the predefined threshold value for the capacity utilization is reached, hydraulic bypasses are connected to relieve the pump, which in turn ensures higher flow and improved heat transfer. This shifts the pump's operating point out of the temporarily allowable operating range and into the continuously allowable operating range and prevents damage due to hot running.

Calculation and evaluation of the pump utilization directly in the drive

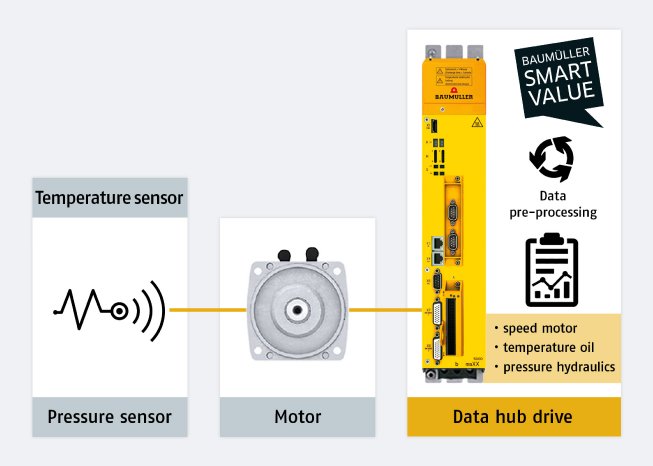

Decisions can be made directly in the drive to avoid machine failures. Thanks to the smart controller function, in addition to thermal overload, other critical states in the hydraulic system can also be detected, for example, dry running of the pump. In this way, the life and productivity of the machine can be increased significantly and failures prevented in good time.

An external temperature sensor is not necessary to calculate the current pump capacity utilization. If the sensors are already available, however, this can be taken into account in the model. In this case, the influence of the oil tank temperature can be considered. If no sensor is available, this is assumed as a constant for the calculation.

The data are evaluated solely in the drive and this relieves the control unit. This saves additional wiring and reduces the susceptibility to faults of the entire monitoring system.