The use of a servo pump is now part of the standard equipment for many mechanical engineers, in part also due to the rising energy costs. But there are also challenges: For example expert knowledge is required for the commissioning and it frequently takes a long time until the production process is optimized and running waste-free. With its new servo pump version, Baumüller has eliminated these challenges and, among other things, relies on a guided commissioning and an adaptive control.

Basic Commissioning Made Simple

The new servo pump software module will be commissioned as additional software with ProDrive. The operating and parameterization tool ProDrive from Baumüller will be used in many applications for parameterization, commissioning, analysis and diagnostics and uses a graphical user guidance to simplify the basic commissioning. Once the new module is installed, a so-called wizard facilitates commissioning. This wizard quickly and easily guides the user through the individual steps. Access to a motor and converter database makes entering these parameters superfluous. The motor/converter combination used only needs to be selected. No entry is forgotten due to the step-by-step guidance through the program.

Higher Parts Quality Without Intervention

The adaptive pressure pilot control is one of the most succinct software extensions of the new software module and directly intervenes in the process. The intelligent control algorithm adaptively responds to different pressure increase speeds. The new software thus allows for a time-optimized overshoot-free pressure jump.

Since the corresponding parameters are automatically adjusted during the production process to achieve further optimization, the adaptive control eliminates or significantly reduces pressure overshoots. The required pressure value automatically adjusts in a time-optimized manner with a smooth transition. An improved production result and thus higher parts quality is thus achieved without changing the machine settings.

Increased Availability and Quality due to Additional Protective Functions

Once the machine is finally ready for operation, it frequently has to meet ambitious production targets. The enhanced protective functions of the new software module monitor, among other things, heavily stressed parts of the servo pump and ensure that machine components are generally stressed less. This automatically leads to a higher machine availability and an improved quality of the end products.

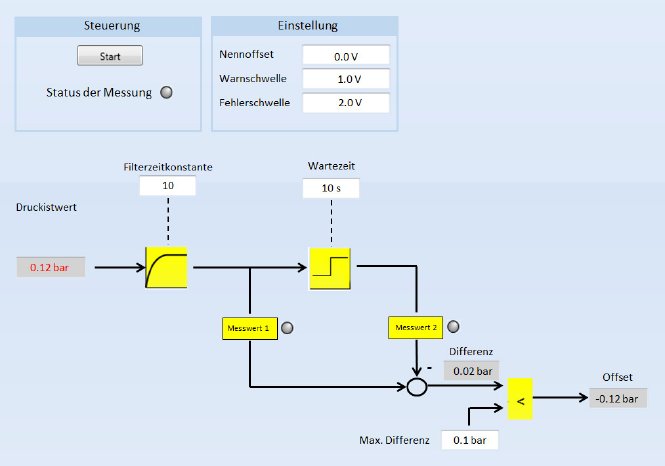

The pressure transducer is a new protective function. The offset adjustment was set up as an Industry 4.0 solution in order to ensure a high process quality in production. If the pressure offset changes, for example due to aging, a diagnosis is triggered by the control unit at zero system pressure. The pressure value for the production process then adapts to the sensor change and is corrected according to the diagnostic findings. This compensation occurs automatically until a necessary replacement of the pressure sensor is indicated. In addition to an improvement of the process and production quality, the offset correction also leads to a lower load of the machine components, thus increasing the availability.

Easy to Integrate Into Any Machine Control

Due to the integrated control unit in the converter, Baumüller servo pumps can easily be connected to any machine control system. The new version is now available for the servo inverter series b maXX 3000, b maXX 4000, for the stackable b maXX 5000 family and for b maXX 5500 mono units.

https://www.baumueller.de/en/products/technology-solutions/servo-pump