The Technology

BAUDIS IoT is the solution for the intelligent networking of machines and systems around the world. Using a retrofittable BAUDIS IoT box or a commercially available industrial PC with OPC UA interface, BAUDIS IoT is used to collect, analyze and transmit data, such as currents, temperature and speed. The system can be used as a retrofittable brownfield solution for existing machines or as an integrated solution for new machines and systems, regardless of the manufacturer of the automation components and the sensor system.

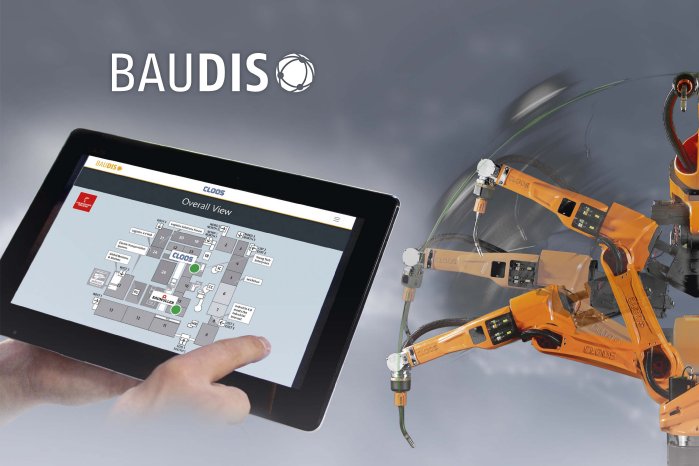

For example, Baumüller is using the two networked trade fair robots to show how several production systems at different locations can be monitored at the same time. The data can be retrieved at any time via a cloud, in this case from the provider T-Systems. Responsible technicians are also notified automatically if there are problems or suspicious results.

With T-Systems, Baumüller has selected a cloud provider as a partner with data centers exclusively in Germany in order to allow for maximum security and compliance with data protection guidelines. Nevertheless, realization is possible regardless of the selected cloud provider.

Predictable Service

When used as a predictive maintenance solution, BAUDIS IoT can, for example, increase the service life of robots, because the robot mechanisms or just individual drives are replaced not after a certain number of hours of operation, but rather depending on the actual axle load.

Unexpected service cases and unnecessarily long downtimes are avoided by the monitoring. Service can be predicted and is therefore more cost-effective.

Intelligent Process Optimization

The advantages are quite different when BAUDIS IoT is used for process optimization. Information can be acquired here about an optimized machine utilization or improved processes by collecting and analyzing data.

Baumüller already uses BAUDIS IoT in its own production. The experts at the trade fair stand will inform visitors of the advantages and experiences of the Industry 4.0 solution.

Expertise Combined in Software

The Baumüller Group with its subsidiaries combines specialists from drive technology, automation and software programming under one roof. All of the expertise from all three areas can be used in the programming of the BAUDIS IoT software and in the algorithms for data evaluation. New findings are constantly incorporated into the system, which thus continuously is developed further and improved.