At the same time, the Baumüller Group contributes to optimized and long-lasting machine operation with intelligent service concepts ranging from engineering and maintenance to machine modernization. You can find our solutions, consisting of systems, components and services for the plastics industry, in Hall 11, stand A41.

Low-maintenance and energy-efficient: Servo pump solution with self-lubricating internal toothing

Baumüller's servo pump combines the advantages of hydraulic power transmission with the benefits of electric servo drive technology. The intelligent control of the drive and the low energy consumption of the components, especially in the partial load range, results in a highly energy-efficient and yet economical solution that machine builders and users have been using successfully in their machines for many years.

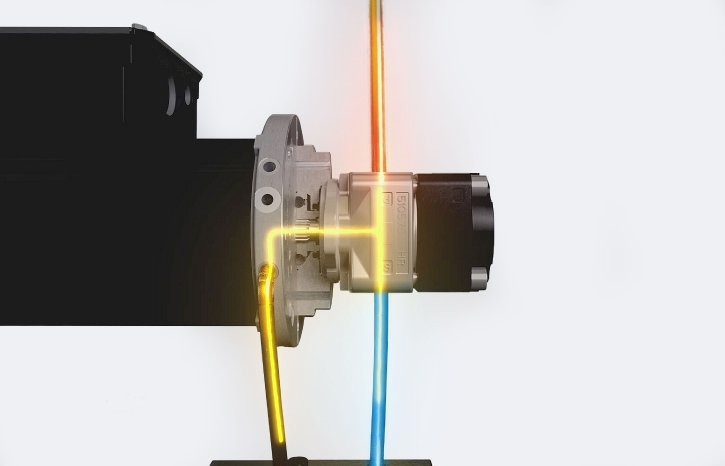

The latest enhancement of the servo pump solution also offers further advantages. For example, the servo pump is mounted directly on the motor with an internal toothing, which has the advantage of a shorter installation length and therefore a smaller machine installation area. Furthermore, direct mounting means that several mechanical parts are no longer required.

Another advantage is the intelligent use of hydraulic oil as a lubricant for the gear tooth system. In both the motor and the constant pump, existing connections allow the hydraulic oil to be returned to the circulation system, thus allowing the leakage flow of the pump to be used for the permanent lubrication of the gear tooth system. There is no need for a grease lubrication of the internal toothing, which is required every 3,000 operating hours on average. The machine can operate without interruption, thus increasing productivity.

The structural change also offers a further customer benefit. Since the holes for the connections are on both sides, the motor can be installed horizontally or vertically, depending on the application. This means that the motor position can be freely selected and adapted to the respective machine design.

With this solution, Baumüller is supporting the objective of energy-efficient but highly productive and low-maintenance production.

Adaptive pressure precontrol Ideal for bio-based plastics or recyclate

The adaptive pressure precontrol is a significant improvement of the software modules of the control function in the new servo pump software version V2+. The conversion to biodegradable materials made from biomass – e.g. corn and sugar cane – makes the parameterization of the plastics machine much more challenging. The intelligent control algorithm adaptively adjusts to different pressure rise rates, i.e. the parameterization only has to be set once and is then automatically regulated. The software enables an overshoot-free pressure jump in minimum time, thus ensuring an optimized process sequence.

Since the corresponding parameters are automatically readjusted during the production process, the adaptive control eliminates or greatly reduces pressure overshoots. The required pressure value is set automatically, with a smooth transition and in milliseconds.

The solution is integrated in the software package of the latest servo pump version V2+ and makes a major contribution to the use of renewable or recyclable raw materials (such as recyclate) in the plastics industry.

New power supply units for high performances

The converter series b maXX 5000 includes feed-in and regenerative units as well as drive units, which can be quickly and easily combined by an integrated drive connect system. This allows the machine builder to benefit from low installation costs and short commissioning and service times. The controllers are available in the cooling methods of air, water and oil and, thanks to their high power density, boast a very small installation space. The power supply units have now been expanded to include peak output of up to 300 kW. Ideal for the plastics sector, as dynamic movements, such as the opening and closing of the injection mold or for injection, require high peak performance at short notice. With a peak current of 420 A, the large axes are ideally suited for maximum dynamic performance.

The energy-efficient solution scores with its very compact design and high power density, enabling the production of precise plastic parts.

Direct ejector for injection molding machines

The DSC1-135 electric ejector drive is a special highlight. The direct ejector is a high acceleration drive specially designed to meet the requirements of the plastics sector. Plastics machine manufacturers benefit from a special mechanic interface for spindle connection and from the high overload capability of the motor. In addition, the motor has a special bearing to compensate axial forces and features very good dynamic properties as well as a space-saving type of construction. In turn, this permits a very compact machine design and replaces mechanical transmission elements such as belts.

Faster time to market: new ProSimulation software

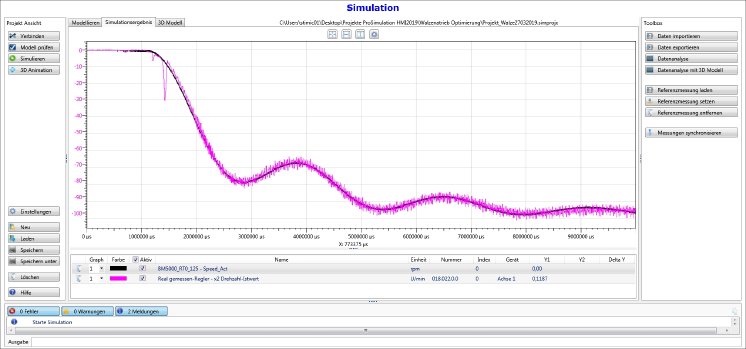

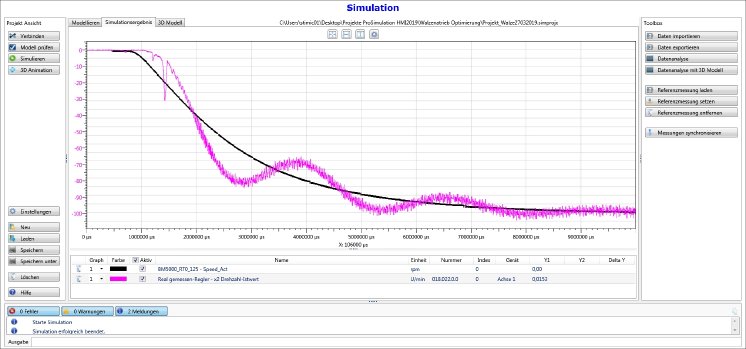

Virtual configuration and testing of automation systems: The newly developed software ProSimulation provides customers with a platform for getting started with the world of simulation quickly. The new tool simplifies the virtual design, optimization and commissioning of plastics machines and systems. Depending on customers’ levels of experience, they can quickly set up their own simulations and applications using the basic library or import existing software models thanks to open interfaces.

The advantages of ProSimulation include time and cost savings in the development and commissioning of new machines and systems as well as the optimization of existing plastics machines. In addition, the company can build up urgently needed simulation expertise for the future, thus building competence in the areas of Industry 4.0 and digital twins. ProSimulation expands the functional range of the ProDrive software, which allows quick and easy commissioning, parameterization and operation of the b maXX 2500, 3300 and 5000 converter series.

ProSimulation permits virtual parameterization to optimize machine behavior. This represents real added value for the plastics industry, because increasingly shorter development cycles in mechanical engineering mean that innovations can be tested - even offline - within a very short time, thus laying the foundation for improved and more environmentally friendly plastics production in the future.

Greater performance: compact water-cooled servomotors

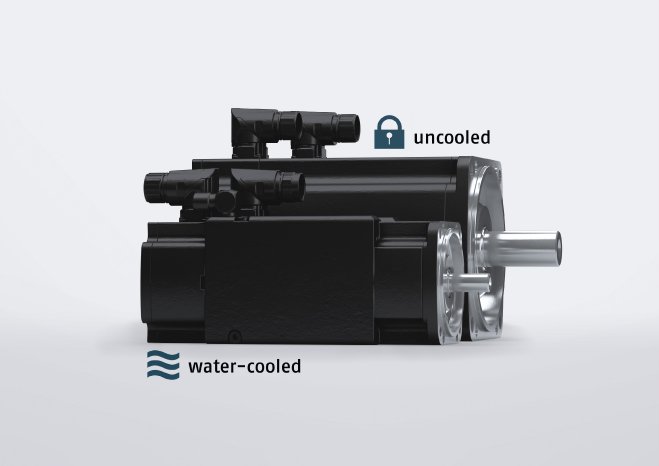

Baumüller is expanding its range of servomotors to include the water-cooled models in sizes 45 and 56. With their space-saving installation and very high power density, the small models really come into their own with their water-cooling benefits. This enables motors installed in very tight spaces to be used at high power ratings. For the machine manufacturer, this means optimal mechanical properties, lower costs and better efficiency.

In addition to the cost savings, the small water-cooled models also offer further advantages when it comes to installation space: With regard to external dimensions, the range of enclosures is structurally identical to a non-cooled version, and therefore combines the benefits maximum cooling with minimum dimensions. Another advantage offered by heat dissipation through the cooling medium of water is that the motors can be placed next to one another even when installed in tight spaces without causing each other to heat up.

Low-maintenance direct drives with high torque and high performance

The high-torque motors of the DST2 series are a low-maintenance and energy-efficient solution for the plastics sector, as they enable a high torque of up to 80,000 Nm over the entire speed range, thus ensuring high performance. The motors are currently available in seven sizes between 135 and 560 and can reach speeds up to 2000 min-1 and an output of up to 1150 kW. Even at low speeds, they deliver very high torques and also score points for their outstanding true running characteristics and very high control quality. Additional advantages include their robust design and their smooth, dirt-resistant housing surface.

Life-cycle management worldwide

In addition to the development and manufacture of automatization components, Baumüller as a group of companies provides numerous services for mechanical and plant engineering and for machine operators. From project planning, design and engineering through assembly and commissioning to maintenance, retrofitting and relocation, Baumüller offers support over the entire life cycle of machines and systems. With over 40 branches worldwide, Baumüller is a globally reliable service partner with decades of local worldwide experience. Baumüller attaches particular importance to the sustainable and resource-saving production of intelligent drive and automatization solutions.

Baumüller Group

K 2019, 16 - 23 October 2019

Hall 11, stand A41 – Düsseldorf Exhibition Center, Düsseldorf