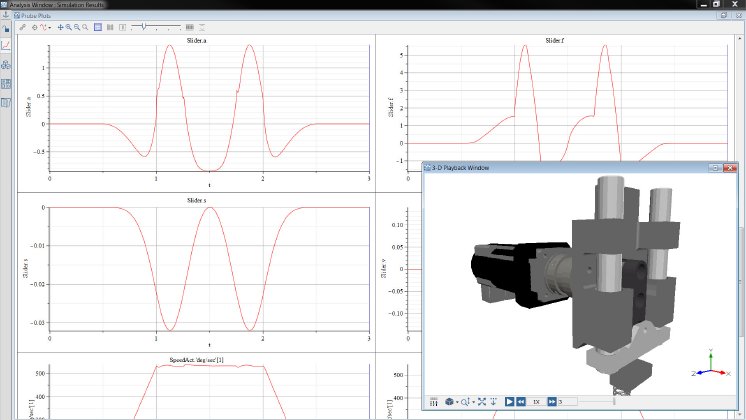

At Hannover Messe 2018 in hall 14 at stand H12, Baumüller is using the example of an automation solution for servo presses to demonstrate how modeling and simulation are used to design and simulate optimal drive and automation components for different machines. This is possible by creating a digital twin, which represents the expected machine behavior already during the development stage, even though the machine does not (yet) really exist. In addition to reducing the development time, this also significantly reduces the effort for commissioning. Software functionalities and controller algorithms can already be tested at an early stage on the virtual machine. Structural and systematic errors are thus detected and corrected at an early stage.

Baumüller also supports mechanical engineers in the model-based design of the electric drive train. The data from these models is provided to the manufacturer in the project planning phase for the new machine. The models obtained through the simulation help the machine manufacturer during the design phase of a new machine. The modeling and simulation lead to a faster time-to-market as well as a higher level of efficiency and quality. Baumüller also offers engineering services for simulations and, when necessary, realizes the entire machine design for its customers, e.g. for presses, based on the model data of the planned machine. Baumüller is thus a competent partner for the mechanical engineer in all phases of implementation.

Simulated Application Optimization

Once the machine is complete, the model can also be used to optimize the production process. In this way, experts can simulate the interplay of different machine components and identify potential improvements. In addition to significantly shortened development times, the customer also benefits from a faster and easier commissioning.

All in all, modeling and simulation makes it possible for the mechanical engineer to achieve a more efficient and higher quality development process.