Wear-free and maintenance-free

Micropulse transducers work without making any contact and are entirely wear-free and maintenance-free, providing the user with an extremely long service life.

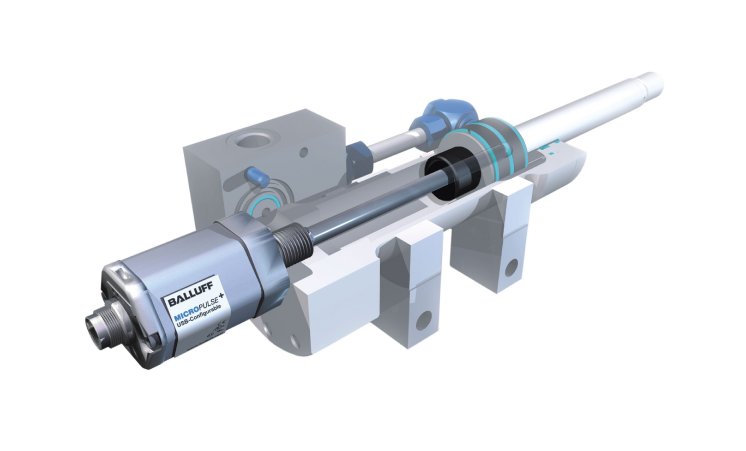

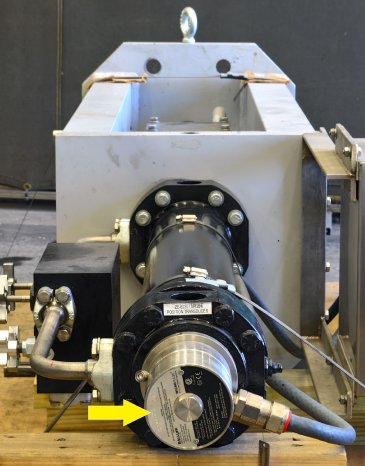

For measuring the position feedback of a valve, the transducer is installed on the back end of the drive cylinder. The actual sensor element is installed into a hole that runs lengthwise, passing through the piston and the cylinder rod and reaching over the entire mechanical stroke length. A magnet ring, located in an indentation on the end face of the piston, acts as the position encoder.

Partial-stroke testing made easy

Logging the speed of the valve movement over time allows the user to detect wear, corrosion or abrasion in the valve before they worsen and cause negative effects. Common symptoms of pending malfunction may include such aspects as the valve reacting slowly or with a delay, or its required deflection is not completely achieved.

Ex models for global use

Explosion proof models of Micropulse® transducers from Balluff are some of the few position-feedback devices on the market that not only have all basic certifications from start to finish, such as ATEX (EU), IECEx (international), NEC (US), CEC (Canada), but also additional regional qualifications for India, Japan, and Korea. Not only does this simplify the design and global sale of standardized systems, it also helps to prevent expensive errors in the project planning phase.