The practical example was developed jointly by ifak, Aucotec AG and the IGR (Interessengemeinschaft Regelwerke Technik) for the presentation at the NAMUR main meeting. All four cases were based on the IGR pilot plant in the Industriepark Höchst.

Web connection and consistent change documentation

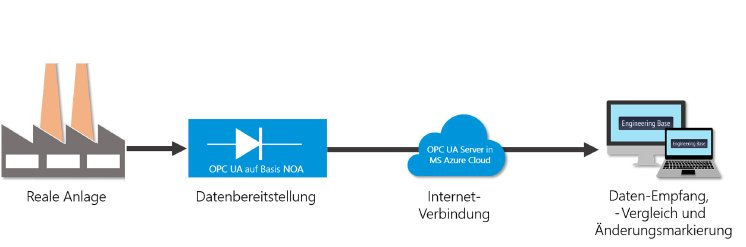

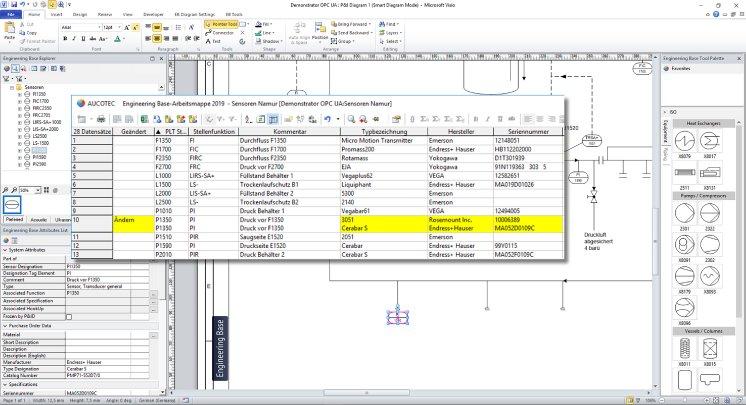

The Engineering Base (EB) cooperative platform from system developer Aucotec can not only communicate with a plant by virtue of its understanding of OPC UA and its web connection. EB's versatile data model also reflects any changes to a real object in the plant automatically in all its documented representations, including P&ID, circuit diagram, BOM, etc. EB also has a data tracking function and a history display, so it is clear who changed what and when.

Automatic documentation of information provided by the plant

For the live demonstration, the pilot plant was connected to Aucotec's Azure Cloud via its OPC UA server. EB receives the live data from the plant at certain intervals. Information on the change is then shown at every point in EB's data model where the sensor appears. Everyone involved immediately knows whether there are any consequences and what they are: for example, adjusting the wiring, updating the specification sheets or generating new revision statuses.

This is a dream come true for the operators: the plant automatically reports changes to its as-built status and the documentation always reflects the latest version, with no redlining, no paper and no manual transfers. Maintenance and revamping work is made considerably easier and clearer. The digital twin ceases to be a snapshot. EB is the first system which can permanently maintain the twin status.

"A massive step forward"

Prof. Dr. Christian Diedrich was impressed by the solution: "It brings us a massive step forward. In just a few seconds, the exchange is not only detected, but it can be automatically incorporated into the documentation, meaning it is always kept up-to-date. With file-based systems, this kind of communication with the plant would only be of limited help, as changes can only be implemented for specific sheets."