"Integration competence is the key to being able to realize the concept of a complete digital twin in the engineering process," explaines Uwe Vogt, Executive Officer for Engineering at Aucotec AG. For many years, the software developers have focused on the particular openness of EB - both for cross-disciplinary, collaborative work as well as for close connections to more specialized engineering or ERP tools. Vogt says, "We want planners, designers and project managers to always be able to use the optimal tool for the respective discipline; an all-round tool can only ever be a compromise."

Integration package: from 3-D to production

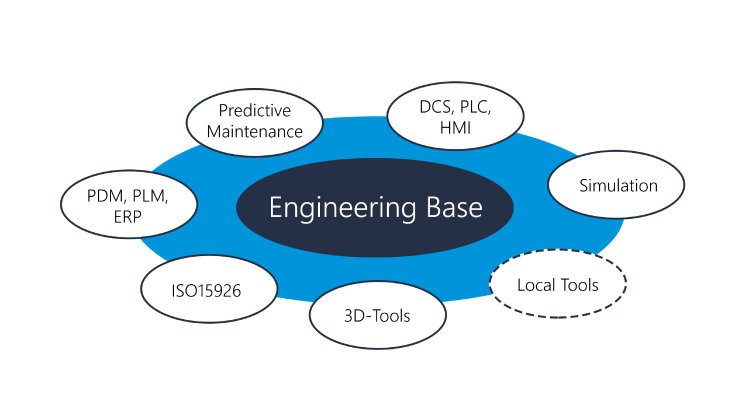

With its central data model, EB already combines inherently diverse disciplines, for example, basic and detail engineering, and simultaneously to boot. However, Aucotec's integration package also provides links to different ERP, 3-D or automation systems, as well as predictive maintenance, simulation or production.

Here, Aucotec uses several integration approaches. A whole series of ready-made interfaces can be easily inserted via "plug and play", for example, for 3-D, PDM or ERP systems. Some links, for example, to the offline editing of EB data by suppliers with third-party systems, can be easily configured without any programming knowledge. There is also the option in EB of installing customized integrations such as web services for mobile maintenance, for example, via .Net. If necessary, Aucotec assists customers here with the necessary programming knowledge.

Forgetting about worrying about forgetting

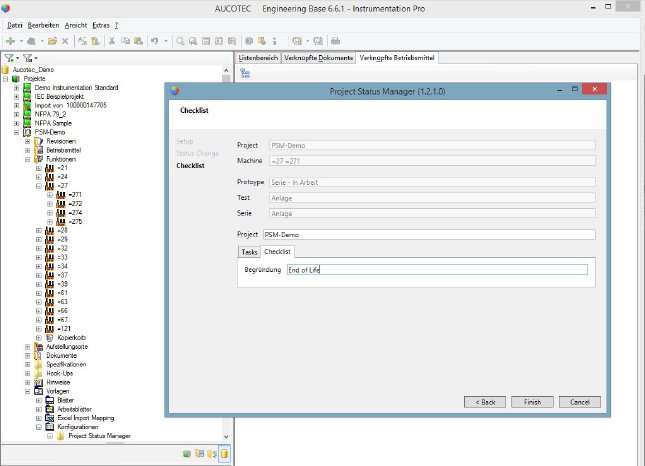

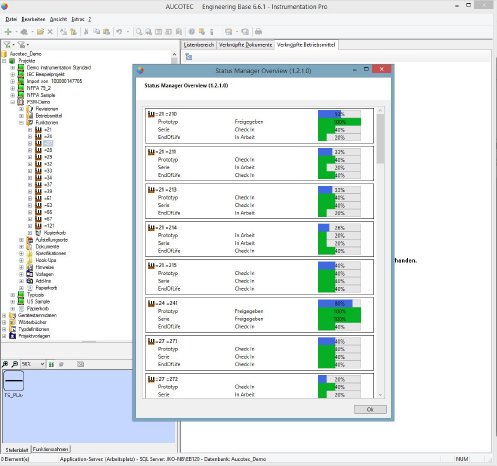

"Openness for integration is crucial, especially in relation to Industry 4.0, but it is the automation of data integration which completes the solution," says Executive Officer Uwe Vogt. The new Project Status Manager, which can be adapted completely freely and thus in a future-proof manner to every workflow, achieves security and saving of time as a central management tool. "Users don't have to worry any more about forgetting steps or mixing up versions," according to Vogt. A large German machine manufacturer is already putting this tool into practice for data exchange with SAP.

Aucotec at Hannover Messe (Hanover Trade Fair): Hall 6, stand K 28