The issue of calculating first pass yield (FPY) and other IPC quality metrics has become increasingly important in light of the increase in subcontracting the production of high technology products. Project teams and their leaders need accurate estimates of new product yields to plan and budget for test, troubleshooting equipment and engineering resources. In addition, management needs to benchmark potential suppliers in order to determine their manufacturing quality.

In quality based test models, the cost of test is derived from FPY defect prediction based on the quality analysis of the product design and each step of the manufacturing process. For all the cost drivers, parts per million (PPM) defect rates are calculated for each manufacturing process operation. The defects generated are then summed up to the product level and the best test strategy is developed for reducing the overall test and troubleshooting costs.

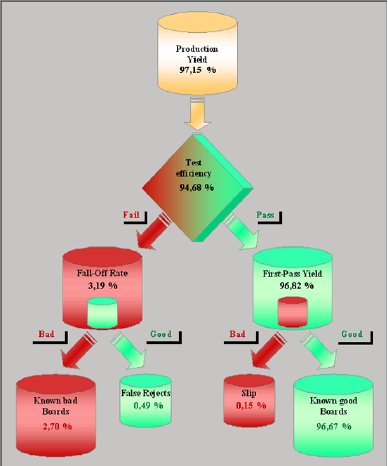

The key metric in understanding the quality of a delivered product is the "slip", or "escape rate". An "escape" is a defect that has not been captured by the test process, but instead is detected by the end-customer. When defects are exposed by the end-customer, they are quite costly and are liable to damage the company reputation.

Mr Christophe LOTZ, Managing director of ASTER said: "TestWay Express is a perfect solution to answer a crucial question: How can the number of products that are shipped with defects introduced during manufacturing, be minimized in order to reduce potential returns?"

TestWay Express can estimate the production yield by importing the defects per million opportunities (DPMO) expressed as PPM, in real time from the manufacturing process and tune the manufacturing test strategy to provide the optimal test coverage to identify the defects for any given product and minimize the slip. Because a board test passes, it doesn't necessarily mean that the board is good, since the test coverage could be extremely poor. So it is increasingly important to link defects using IPC quality metrics with test coverage within TestWay Express.

Test coverage is estimated using theoretical models for a wide range of test and inspection strategies such as APM, AOI, AXI, BST, FPT, ICT etc, and Functional Test, that can be tuned to reflect the test and measurement capabilities of the target tester. Once the test/inspection programs have been completed, TestWay Express can read the debugged test program or test report and compare the coverage between the estimated and measured analysis using industry standard metrics, and identify any misalignment.

More than 45 coverage importers are available for a wide range of the test/inspection machines used within the industry such as Acculogic (BS, Scorpion, SPRINT); Aeroflex (4200, 5800); Agilent Technologies (i1000, i3070, 5DX, SJ10, SJ50); ASSET; CHECKSUM; CORELIS; CyberOptics, DrEschke; GOEPEL (CASCON, OPTICON); JTAG Technologies; Mirtec; MYDATA, OMRON; Orbotech; SAKI; SEICA; SPEA (3030, 4040); TAKAYA (APT8000, APT9000); Teradyne (Z1800, Spectrum, GR228x, TS124); TRI (TR7500, TR8001); VI Technology; VISCOM; XJTAG and YESTech.