Environmentally friendly, powerful yet easy to apply - Bentogliss® 121 fulfils all these requirements. The totally solvent-free release agent minimizes ecologically hazardous, volatile organic compounds (VOCs). Therefore, foundries effectively avoid emissions in the casting process.

Using the release agent Bentogliss® 121 also facilitates the molding process by significantly reducing adhesive forces between the pattern and mold walls. This, in turn, reduces wear and tear on patterns and contributes to their greater durability. A barrier layer also prevents corrosion on patterns and varnish, which offers protection during storage.

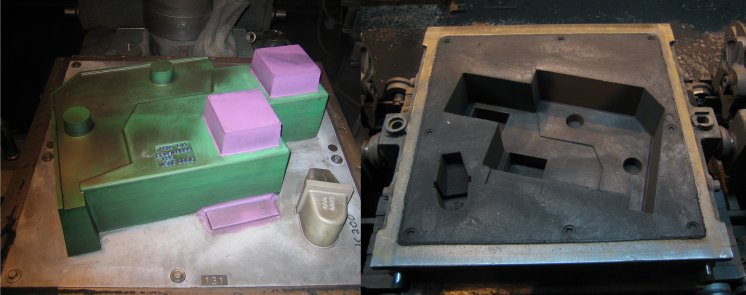

Using Bentogliss® 121 optimizes the separation of molds from patterns and consequently ensures zero-defect surfaces (figure 1). Since it is also wax and silicone-free, build-up on molding boxes and coating problems are effectively eliminated. Overall, maintenance costs for the patterns are reduced many times over. The new molding release agent from Ashland-Südchemie-Kernfest thus makes a further contribution to process efficiency in foundry operations.

The development of emission-free foundry products is a high priority at the Ashland-Südchemie-Kernfest GmbH research and application centers. "Since secondary measures for subsequent purification of emissions are connected to high investments, primary measures acquire a particular significance", Dr. Ulrich Girrbach, Director Sales & Marketing, comments on this strategic development process. Ensuring and further improving environmental friendliness with regard to emissions, performance and recyclability are a primary target in Ashland-Südchemie-Kernfest GmbH's product development.

You can find further information about the complete program of release agents offered at www.ask-chemicals.de.