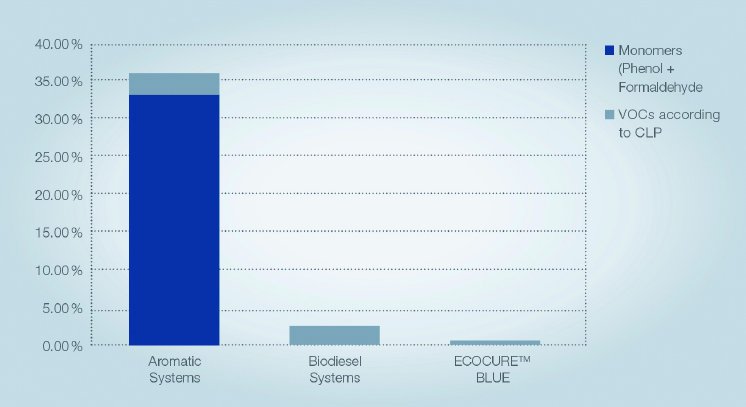

Until now, cold box systems – even advanced cold box systems like ECOCURE™ High Efficiency or ECOCURE™ Solventless Technologies – are all classified as dangerous goods on the safety data sheet. ASK Chemicals is now launching ECOCURE™ BLUE, the world’s first cold box part 1 that does not contain any hazardous ingredients according to CLP regulation. As a result, ECOCURE™ BLUE is actively contributing to the creation of a safer and healthier work environment (Table 1).

There are basically two phenomena that cause emissions in the foundry. Evaporations in the core shop and decomposition processes during pouring, cooling and decoring. ECOCURE™ BLUE has the lowest level of volatile organic compounds and can be considered as VOC-free according to European regulations. Additionally, the new technology contains less than 1 % free phenol and non-detectable free formaldehyde, which makes it the cold box system with least emissions in the core shop.

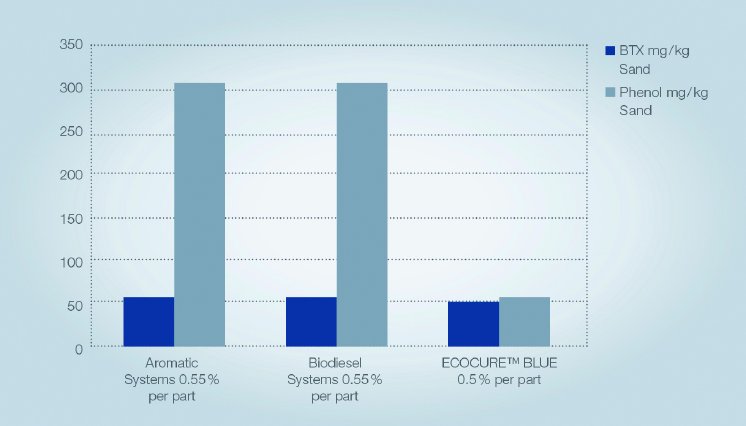

During pouring, cooling and shakeout, there are basically two kinds of emissions: BTX and phenol emissions. The BTX emissions are more likely to stem from the polyurethane pyrolysis than from the solvent package of the binder. Therefore these BTX emissions can only be significantly reduced by reducing the binder quantity and by increasing the efficiency of the binder, as the ECOCURE™ binders do. With less free phenol, the ECOCURE™ BLUE enables the phenol emissions to be drastically reduced during pouring.

“With its new ECOCURE™ Blue platform, ASK Chemicals has surely developed one of the big achievements in the field of cold box technology for the next few years,” Phil Vernon, Chief Business Development Officer at ASK Chemicals, states. “Our team of R&D researchers was able to formulate a cold box binder that is, performance-wise, equal to our well-known high-efficiency ECOCURE™ binders, while considerably reducing the environmental impact.”