Mario Metzger, Product Manager at Arnold summed up these consistent efforts: "by getting involved in the R&D process at an early stage, we have been able in recent years to make a sustained contribution towards the trend for direct screw connections for plastic fasteners in the automotive industry." The argument gains credence in that plastic is increasingly in use as a material in the automotive industry. The moulding capacity, the weight and recyclability of the synthetic materials are positive points in favour of using them in future models. To an increasing extent Remform fasteners from the Arnold range ensure that plastic components stand firm from a costs point of view at all levels of added value.

Costs are saved throughout the process chain A costs study carried out by Arnold, together with leading companies from the components industry, showed that a sustained reduction in fastening costs could be made over the entire process chain by using plastic direct fasteners. As opposed to manual screw fasteners with metric inserts, an average saving of €0.26 per fastening could be made by using Remform direct fastener technology. Half of this potential saving (€0.13) comes from assembly costs. A further €0.10, representing 38% of the saving, is due to reduction of manufacturing costs, and only €0.03, or 11%, is down to the actual cost of the parts. Even where the manufacturing process is fully automated, already cutting assembly costs by €0.08 since no personnel is required, the savings potential is still €0.20 per fastening.

These effects result from the special self-tapping capacity of Remform screws. Remform fasteners are particularly advantageous where the core hole is pre-cast. This automatically eliminates the costly processes involved in preparing the screw location. The cost of inserts is completely eliminated from the overall calculation, along with the manufacturing costs involved in handling the inserts. At the same time the fast screw-in speed cuts production time - increasing the potential of direct screw fasteners even further.

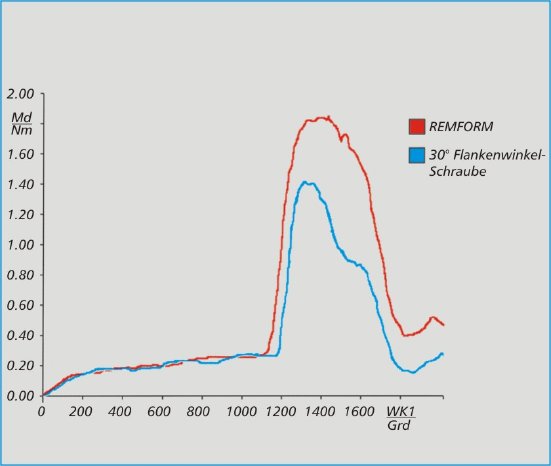

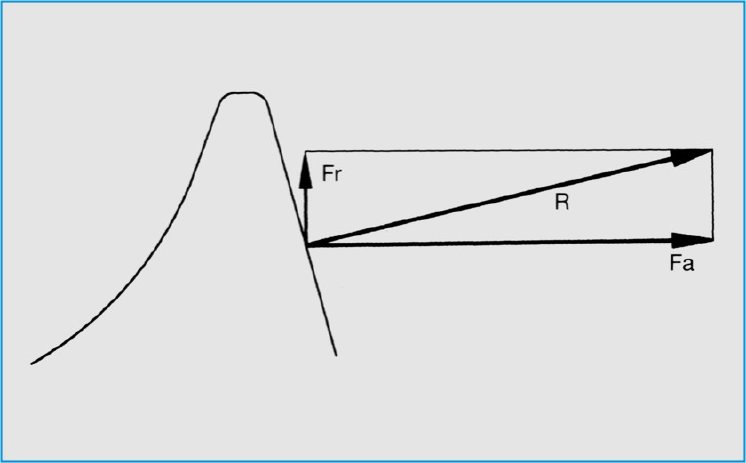

The advantages over metric variants The asymmetric thread geometry of Remform screws is forging new areas of application for plastic fasteners, whereas in the past the metric variant was mainly used for narrow tappets.bosses. The screw-in force incurred is automatically guided towards the axial - and thus the correct - direction. Compared with 30-degree low angle screws the results of overturn torque, strip load and the difference between minimum overturn torque and maximum screw-in torque is often well over 30 percent.

To ensure that the fastener location cannot be damaged, the asymmetric flanks of the latest Remform generation ensure that edge stresses are reduced as the thread is tapped. At the same time the diminishing flank angles towards the crest of the thread reduce the radial stresses that could cause the tappetboss to explode.

Patented thread geometry Remform screw connections provide completely secure fastenings. To improve material flow, the flank that is averted away from the screw head has been provided with a radius. The steep side that has moved towards the screw head catches the displaced plasticmaterial and thus automatically raises the flank overlap. This guarantees the high cross-thread forces with tensile force and torque. At the same time the steep flanks ensure that most of the force is steered axially, thus increasing the likelihood of the nut thread breaking up. The wide stress ratio tolerance between forming torque and overturn torque at the moment of tensioning torque provides additional safety tolerance; this means that screws that are fully tightened - always.

In the Remform technology Arnold's fastening specialists have convincingly demonstrated that the application range for self-tapping screws in direct plastic fastenersdirectly into plastics can be expanded greatly. Remform screws offer cost savings throughout the entire system cost chain. This opens up maximum cost-cutting potential in assembly and processing, whereas the cost of the material represents a negligible amount. At the same time Remform fasteners improve the mechanical properties of the fastening.