In the field of fused filament fabrication (FFF) 3D printing technology, black-specks can potentially develop in printed parts or at the regions of the printer where the melt exist; such as the nozzle as well as areas around the nozzle. Should this occur, it can be attributed to poor thermal management during the printing process. While the material science governing the formation of the black-specks suggests uncontrollable thermodynamically driven changes (gradients in concentration, pressure or temperature) within the melt as a prerequisite, it goes without saying that temperature plays a cardinal role.

The possible sources of the black-specks in FFF 3D printed polymers are:

- Degradation of the molten filament at the joint of the heat-break and nozzle

- Degradation of the melted filament inside the nozzle shaft

- Poorly designed nozzle tip-area such that the melt collects at the exposed surface and then degrades

- Irregular thermal loading of the melt by the heating elements

- Melt degradation due to presence of foreign particles interfacing with the melt

- Prolonged residency of a melt-batch in the nozzle shaft/barrel (HotEnd)

- Too high processing temperature

For high temperature polymeric materials such as PEEK, a tight rein on temperature based activities in the printer is desirable. Apium’s 3D printers are especially designed to ensure that black-specks do not develop in the printed parts; even for processing temperatures significantly above the melting temperature of PEEK. On the confidence of this technical achievement Apium is able to process the natural coloured (Beige) PEEK for displays, demonstrations and end-user applications. These specks when present in black coloured PEEK are of course not visible or when in richly amourphous PEEK (poorly crystallized PEEK, deep brown coloured) they are hardly visible to human eyes (Figure A).

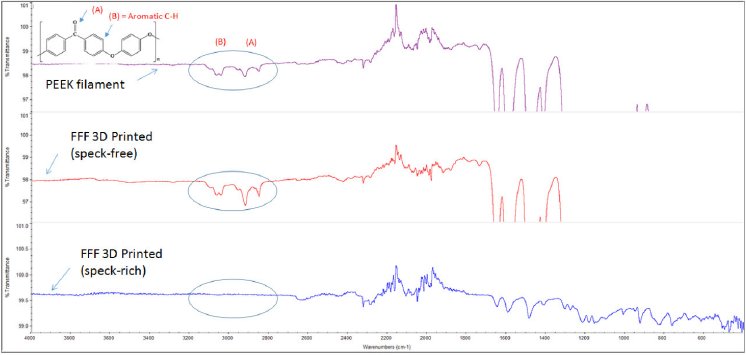

A Fourier Transform Infrared Spectroscopy (FTIR) analysis allows for the determination of the nature of chemical bonds in materials based on the characteristic absorption or transmittance of infrared light by the material at a relatively wide spectral range. FTIR examination of FFF 3D printed black-speck – rich and black-speck - free PEEK samples revealed (spectra in Figure B) that the aromatic group as well as the carboxyl group characteristic of PEEK structure was detected in the speck-free PEEK (filament and 3D Printed samples) while in the 3D printed speck-rich PEEK material these groups were not detected. This result supports incidence of thermal oxidation (burning) of the material with associated atmospheric CO2 observed; representing a change in which the chemistry of PEEK structure is altered (by oxidation) thus depriving the material of the properties which make PEEK unique. It follows then that the black-speck is a burnt mass of contaminant in polymers; PEEK.

The craftsmanship needed to 3D print high quality PEEK parts using the FFF technology has been developed and consolidated at Apium. This achievement allows for the processing of other high temperature polymers using the FFF 3D printing technology without degradation of the material and the formation of blackspecks.

Acknowledgements

The FTIR analysis was performed by the ARC Centre in ADDITIVE BIOMANUFACTURING which is directed by Professor Dietmar W. Hutmacher at the Queensland University of Technology - Australia.