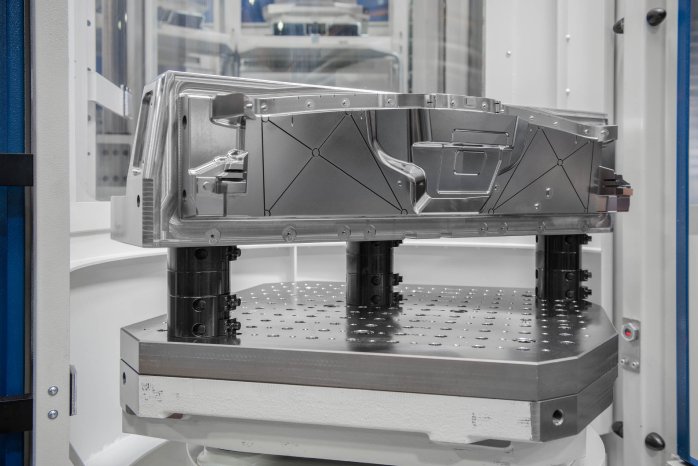

"Today's moulds and tools with their complex contours place significantly higher demands on clamping technology than the products of earlier years," emphasizes Markus Ferstl, head of the milling department at the Formenbau Koller GmbH in Dietfurt-Oberbürg. Today, more and more features are being assimilated into the tools and thus into each assembly and module of a mould. As a result, geometries and contours are becoming increasingly complex. And by the same token, the requirements of workpiece clamping technology are increasing for collision-free cutting in the production of components. In conjunction with five-side processing that is as automated as possible, challenges must be mastered that no one could have imagined six or seven years ago. "Thanks to the modular zero-point clamping technology from AMF, we clamp quickly and with repetition accuracy and at the same time achieve the greatest possible flexibility for largely automated five-side processing," reports Paul Schaffner, who is jointly responsible for

the milling department.

Tool-making places the highest demands today

At the main site of the automotive supplier, which manufactures prototype and series tools or series plastic parts made with them for all known OEMs and suppliers, tools for a wide variety of parts are created on more than 20 machines. Since plastic parts are also manufactured at the other sites in Schwaig and Lupburg as well as in Pécs (Hungary), Mexico and China, the group has developed into a global technology company and specialist in lightweight components. The individual companies develop and produce lightweight interior and exterior components made from intelligent composites such as PU-GF honeycomb, CFRP, SMC or individual hybrid variants. In this way, loading floors, hat racks, CFRP wet-pressed parts and injection moulded parts are created for small batch and mass production in the automotive industry with a special emphasis on lightweight construction. And thus the new Audi A3, new Porsche Macan or SUV models from Jaguar Land-Rover benefit, for example, from the manufacturing expertise of Koller Formenbau just as much as an upcoming electric vehicle from VW.

In the tool-making facility at Dietfurt, 160 specialists manufacture tailor-made injection moulding and composite tools as well as systems and fixtures for external customers as well as for the companies in their own group. This includes both problem-solving expertise from tool-making as well as experience from the series production of parts. Hence, customers benefit from the entire global value chain, including the vision, component development up to the industrialization and series production.

At one time, AMF-Showmobil showed possibilities directly on site

The tool-making experts of Koller in Dietfurt master the challenges every day - since 2015 with the help of zero-point clamping technology from Andreas Maier GmbH & Co. KG from Fellbach. At that time, the AMF Showmobil Andreas drove to the Koller yard. The employees were able to have the technologically leading clamping technology products and solutions demonstrated live and immediately recognized the tangible advantages that can be achieved with modern clamping technology in production. "Ever since that time, AMF's zero-point clamping technology has been indispensable for us," assures Schaffner.

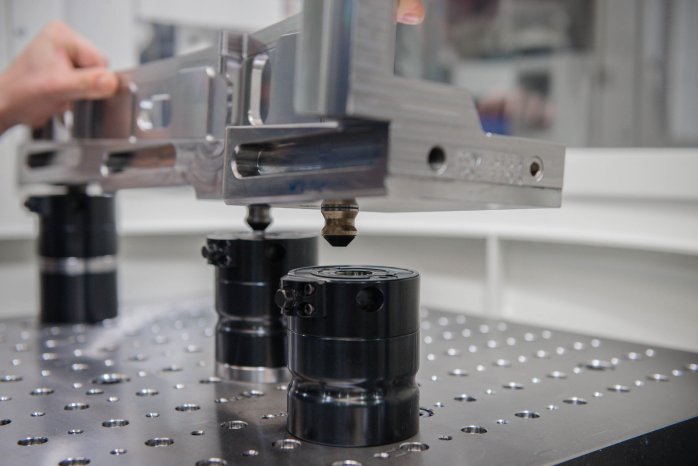

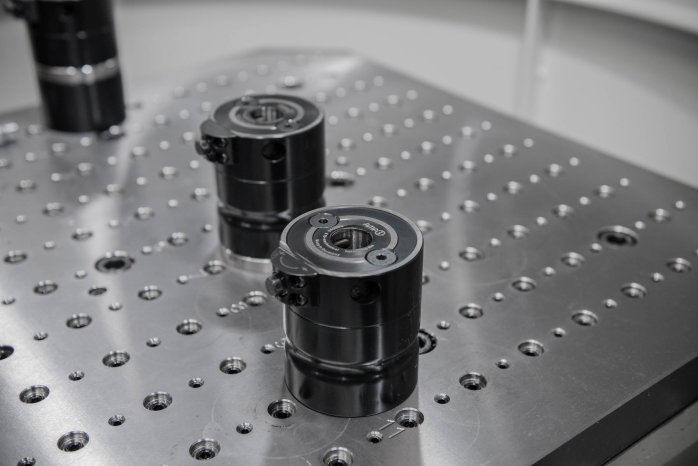

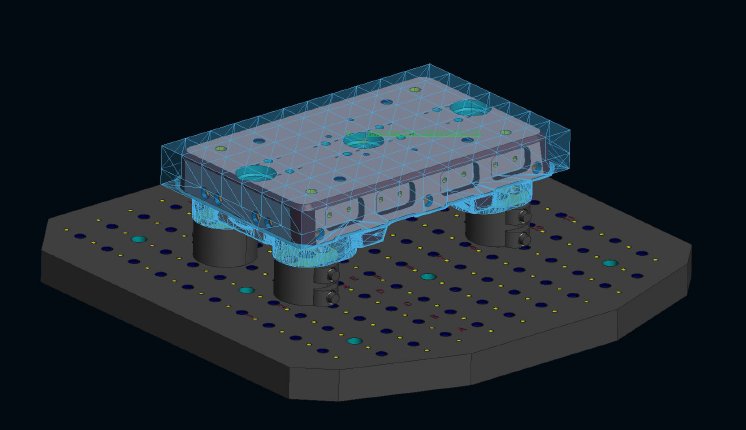

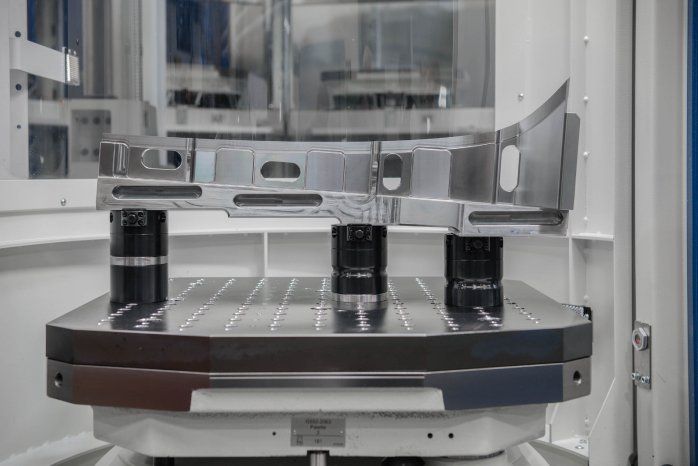

Modular zero-point clamping systems from AMF's extensive standard portfolio are used on almost all of the 22 machines. This includes clamping pallets in the dimensions 630 x 630 millimetres with 214 positioning holes M8 with 15 mm adjustment as well as mechanical assembly clamping modules K10 as single and double modules. The clamping module has high retracting, locking and holding forces. It is opened and locked mechanically. The two companies have cooperated closely on grid plates. AMF supplied some of the plates as well as the drawings for one machine and Koller manufactured

the clamping plates itself.

Visualization in the 3D model prevents collisions

Thus, for example, a five-axis machining center from Grob is equipped with a circular automated pallet changer with 13 pallets. The workpieces are clamped directly on the pallets. The pull-studs with engagement screws in the hardened bushings of the clamping pallets hold the pull-studs of the structural and spacer elements. They are available from 20 to 100 millimetres. With the defined grid pitch, each pallet offers the greatest possible flexibility for positioning the elements. Finally, a zero-point clamping module K10 is positioned at the top, which pulls in and locks the M8 or M10 pull-studs screwed into the workpiece with 10 kN and holds it with 25 kN force.

For direct clamping, the holes necessary for the pull-studs are made directly in the unmachined part. The visualization in the 3D model beforehand is an indispensable aid. Schaffner also explains why: "In this way, we can identify any interfering contours for the necessary five-side processing at an early stage, and our designers plan the bushings in such a way that there is no risk of collision."

"Take along" Zero point for other processes and machines

The components made of different materials are often first roughed and then mostly hardened. After the finishing and other processes, such as drilling or threading, it is often necessary to erode as well. “During all of these process steps, the zero-point clamping technology from AMF brings us significant timesaving benefits, since we also incorporate the zero point that was measured once in all other machines and processes. Thus, with AMF technology we have drastically reduced set-up times and increased machine running times from 80 to 140 hours", reports Schaffner. With appropriate planning, we can also manufacture at weekends with minimal manpower.

Apart from saving time, there is often another benefit, promises Christian Vogel, a sales engineer at AMF. “If workpieces are clamped with our zero-point clamping technology, there are fewer vibrations during machining. This leads to a better surface quality, which shortens process times or sometimes makes subsequent processes superfluous."

Proven solution in Germany also implemented in China

In any case, in toolmaking of Koller in Dietfurt, the clamping solutions with zero-point clamping technology from AMF that have gradually been built up since 2015, have proven their worth. “In fact, so well that we have transferred these solutions one-to-one to our toolmaking facility in Nanjing,” Ferstl concludes. The Chinese subsidiary, which was established in 2018, is also located on a 50,000 square metre property with a 3000 square metre tool-making facility. Tools and products for the Chinese market have been manufactured there since 2019.