Special devices for particular challenges

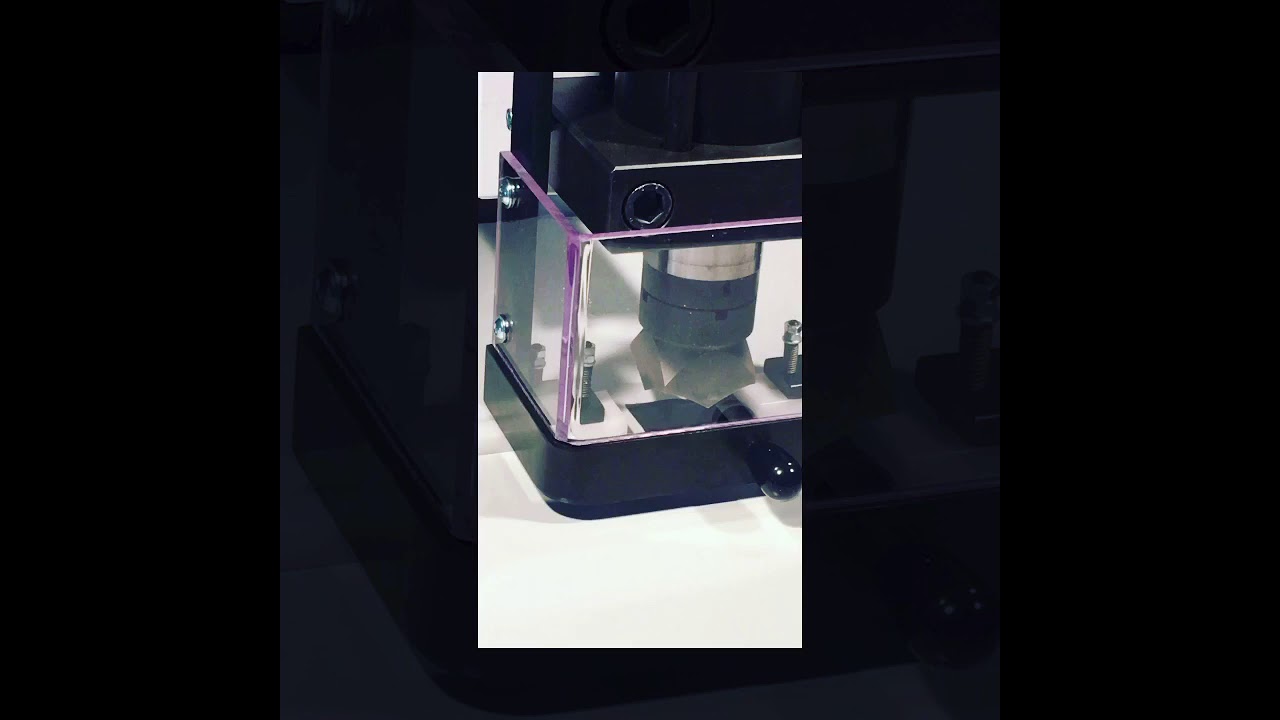

The company with three production sites in Germany, has been manufacturing hydraulic punches since the end of the 1970s. Alfra later expanded the range by adding suitable solution applications. The use of stationary hole punchers makes particular sense when the number of knock-outs or the thickness of the material pose special challenges for control cabinet builders. "If cables have to be routed through the openings, Harting plugs have to be inserted, or an opening for a filter has to be created - the models from the ALFRA PRESS line improve the production processes during punching with a bundle of features," says ALFRA’s technical manager Klaus Pfeifer. Most importantly, they are punching square, rectangular and round openings not only in control cabinet doors and housings, but also in mounting plates, terminal boxes, cable ducts or cable routing plates. The three variants AP 600, AP 400 and AP 250 are suitable for processing switch cabinets or switch cabinet doors with a throat depth up to 600 mm, 400 mm, or 250 mm. Depending on the model, the punches can be used on sheet steel with a thickness between 2.5 mm and 3.0 mm. Stainless steel can be processed up to a thickness of 2.0 mm. In addition, the machines from the AP line are punching plastic up to a thickness of 4.0 mm.

Saving work steps

The clock is ticking for all activities related to control cabinet construction. In addition to speed, precision is required. With all three models, concentrated punching power is at play. This means, that the sheet metal punches used with the AP 250 and AP 400, are hitting the material with 46 kN punching force, the AP 600 is even coming up with 60 kN. ALFRA electro-hydraulic pumps act as drive units for the variants with 250 mm and 400 mm throat depth. An inexpensive "entry-level solution" would be to operate the machine by means of a manual foot pump. A built-in hydraulic unit provides power for the AP 600. The result: The fast punching process alone contributes a great deal to the accelerated sequences, because they take only seconds – just like the swift tool change. Alternatively, panel builders use jigsaws to create the necessary openings. However, this does not only cost valuable minutes, it also produces chips and sharp edges. Further work steps, such as deburring and chip removal, are necessary because the paint on the enclosure is damaged and cables can chafe. There is also the risk of a short circuit due to metal chips in the assembled control cabinet. In contrast to punching processes with manual punching devices, there is no need for pre-drilling with the models of the AP line. The user is achieving a burr-free punching in just a few steps.

Accurate to the millimetre, even at the edges

A company with the goal of producing products close to the needs of control cabinet builders, must immerse deeply into their working world. The machines from the ALFRA PRESS series therefore have various details drafted for the requirements of the industry. One example: thanks to different die supports, users can also punch in areas, which are situated very close to edges. A laser pointer is indicating the centre of the tool. Punching or scribing, to position the tool exactly, is no longer necessary. Instead, a simple marking with a pen is sufficient.

"The swiveling and height-adjustable support arms, which are standard equipment for all our AP punchers, are also practical," says Pfeifer. When using e.g the AP 250 and AP 400, this design makes it possible to put on control cabinet doors, side parts or flange plates in order to process them. Thanks to the attachable folding stops, control cabinet builders can fix the attached parts and punch them in line.

Constant advancement

Each unit in the AP series has functions, that are individually tailored to to the everyday work of control cabinet builders. The AP 600 is punching doors, panels or side panels of all common enclosure types, provided they do not exceed the 600 mm throat depth of the unit. An alternating quick clamping system is creating the conditions for the bending to face either upwards or downwards, and the die bed holder is ensuring that a tool change can be carried out even when the enclosure door is clamped. "In addition, the AP 600 is the perfect punch for large openings, such as those required for the use of fans and filters," explains the technical manager. The AP 250 and AP 400, on the other hand, can be used to process small and medium-sized enclosures as a whole. "So that we can keep up with the demands of our customers, we are constantly developing the devices further," he says. One example is the power bank for operating the laser pointer. This makes the AP 250 and AP 400 more compact and mobile because the cable for the power supply no longer takes up space. All three punches are now available in the "clean look" in elegant white. "This means that the look of the devices emphasises their high quality even more clearly," says Pfeifer.