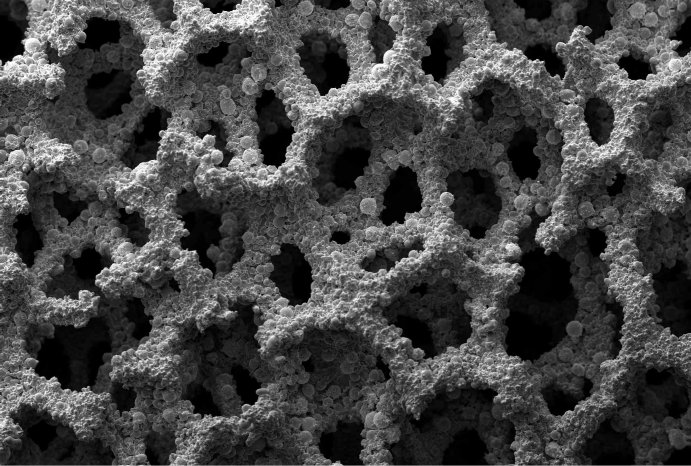

High temperature and corrosion resistance, coupled with a very good soot storage capacity, are among the basic requirements of an effective substrate for diesel particulate filters. The iron and nickel-based alloy metal foams from Alantum Europe GmbH achieve these properties thanks to a patented, stable, and continuous production process. During this process, metal foams are coated and thermally treated with a high-alloy metal powder that is tailored to the particular application and design. Fusion takes place, contributing to an extreme enlargement of the specific surface of the light metal foam and resulting in a good filter effect. At the same time, the temperature resistance of the thermal conductive alloy foam increases up to 1,000 °C with peaks of up to 1,200 °C. "The composition of the alloy can be modified and customized within a broad range thanks to the production process also enables various properties of the alloy foam to be adapted to meet specific customer requirements. Additionally, a catalytically active coating can be applied either completely or only to zones or layers," adds Thorsten Blume, Director of Applications and Technical Sales at the Sauerlach-based (Germany) company.

Free design for closed DPF systems

In contrast with current market standard substrates, the homogenous alloy foam remains flexible, ductile, and can be cut at any length, allowing it to be rolled, stacked, bent, and shaped, for example. It is also possible to sinter the material, usually manufactured as sheets, into stacks during the production process and to subsequently cut these. Even very complex structures can be manufactured in this way. The high flexibility of design in the construction of DPF components and other exhaust aftertreatment systems is the result of the virtually unlimited ductility and flexibility of the alloy foam. The shape and size of the diesel particulate filter can therefore be adapted to suit the required installation space, which is not feasible with the substrates currently available. "Semi-trailer tractors with a short wheel base present a particular challenge, for example. The possible integration area is extremely limited here and, in most cases, quadratic or rectangular. Classic wall-flow substrates and partial flow filters require sophisticated, gas-tight auxiliary constructions," Blume explains. There is no need for possible downstream silencers thanks to the alloy foam's good sound-insulating properties.

A further benefit is the simple canning that only requires a connection to the external housing. As the system is able to operate without a filter bed, it is possible to manufacture closed DPF systems more cost effectively.

Definable deposition rates thanks to different pore sizes

Alantum alloy metal foams are offered in the following standard pore sizes: 450, 580, 800 and 1200 µm with material densities of 0.695, 0.581, 0.448 and 0.351 g/cm3. Other pore sizes and densities can be supplied on request. The 100% open pore substrate has a very permeable structure with a large specific surface area, on which the particles can be deposited. The particle deposition rate can be set to meet efficiency requirements in a range between 50 and 80%, and in specific cases, up to 90%, depending on the number of foam layers and their pore sizes. Compared with partial flow filters, there are no blow-off effects. As the alloy foam is made solely from metal and does not contain any environmentally harmful substances, it is easy to recycle.

Simple regeneration thanks to DPF/DOC integration

When regeneration of the DPF is required, the alloy metal foam has advantages to offer for both passive and active processes. For example, the high temperature resistance and thermal conductivity of the substrate ensure that even temperature peaks will not lead to problems. As the material can also be heated inductively, regeneration can also be carried out contact-free, as in in off-road vehicles, diesel locomotives, and stationery diesel engines for example. If regeneration produces ash, because of additives, for example, these can be washed out in a simple and environmentally friendly manner.

For passive regeneration, a diesel oxidation catalyst (DOC) can be integrated into the DPF. "In this case, a washcoat is applied to one or several layers of the foam," Blume describes. The significantly larger specific surface area of the alloymetal foam compared with conventional substrates and the high turbulence of the gas stream enable a significant saving in precious metal usage. Using the alloy metal substrate enables cost savings of up to 10% to be realized depending on the design of the DPF.

Certified DPF systems already in use

A certified DPF system has been in use with Alantum's alloy metal foam in the Netherlands since the end of 2007, to reduce the pollutant category of lorries from EURO II to EURO III. Various certified DPF systems have been on the market in Korea since the end of 2006, which are used both in cars and in commercial vehicles.

The substrate is produced at Alantum Europe GmbH in the Bavarian town of Sauerlach. The company also has capacities for prototyping, material, process and production development at this location. A plant for full volume production is due to go into operation in Korea in the spring of 2010.