The construction of AERZEN Turbo blowers is quite simple: A blade wheel, aerodynamically optimised and located directly on the motor shaft, rotates in a spiral housing thus generating the volume flow. The particular challenge of this technology is the high speed range from 20,000 to 70,000 rpm. Besides special motors and a frequency converter, the shaft bearing is an important issue. Standard industrial roller bearings are not appropriate for the occurring loads.

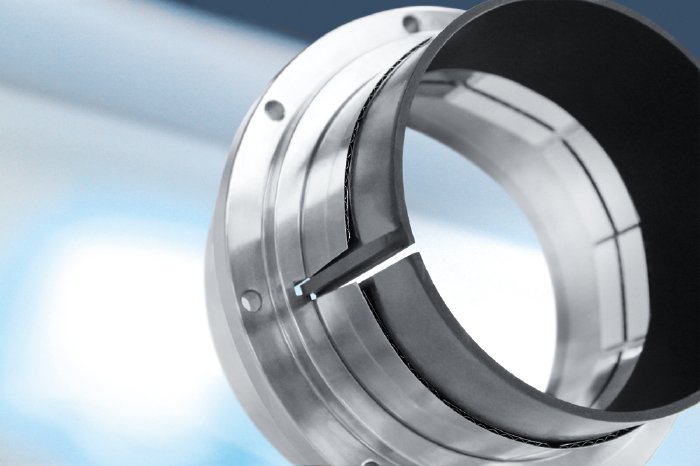

AERZEN has found an optimal solution for this problem: The two radial bearings of the drive shaft and the thrust bearing for absorbing axial forces have contact-free air bearings. The shaft rotation generates, as the turbo blower is started, an eccentric circular motion in the air gap between shaft and bearing through natural imbalance, compressing the air in the gap. With increasing speed, the axis centres itself and is held in contact-free position by an air pressure of over 30 bar. This system is completed by a two-component coating, free of maintenance, which serves as friction partner between the highly finished surfaces when the turbo machine is started and the air cushion is formed within fractions of a second. The PTFE layer provides good sliding properties - lubricant-free. A sheet steel, when rolled into an undulating shape, supports the lubricating layer of the bearing and absorbs vibrations to protect the housing.

Turbo blowers of other manufacturers use magnetic bearings. Magnetic bearings basically work as good as air foil bearings, but they have many disadvantages compared to the AERZEN bearings: The solenoids, arranged circularly, require a highly complex control system and an uninterrupted power supply. This makes the magnetic bearing expensive and more maintenance is required, which

considerably increases life-cycle costs. As a matter of fact, the complex system of magnetic bearings is likely to be subject to errors than the air foil bearing system is. The air bearing principle does not require any electrical, mechanical or pneumatic controls. This system is of simple design. It works efficiently, inexpensive and requires only low maintenance.