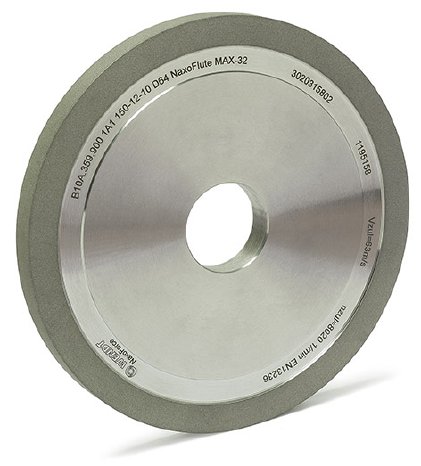

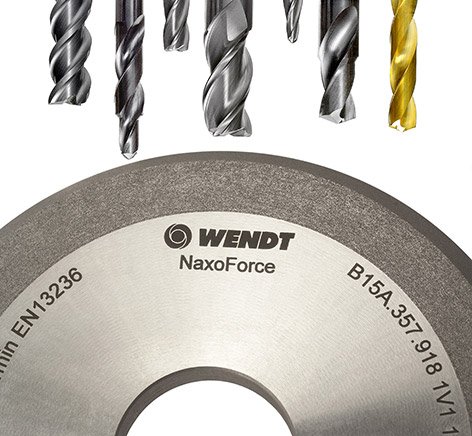

For these products, the company has developed an entirely new, hybrid bonding system. It combines the advantages of several bonding technologies at once in a highly improved dimension: the free cutting properties of resin and ceramic bonds in conjunction with the edge and formholding stability of metal bonds. This series of grinding wheels thus opens up entirely new possibilities in the manufacture of rotating cutting tools. Even sharpening of these innovative wheels after truing is no longer necessary.

Fast Machining of Grooves up to Eight Millimeters in Depth

Whereas previous products had to be run with shallower cutting depths and slower feed rates in order to protect the workpiece and cutting tool against heat damage, the new grinding wheels are suitable for rapid deep cutting of grooves in depths of up to eight millimeters in one pass. In many different applications, they have already demonstrated their high material removal rates and excellent stability.

About Winterthur Technology Group

The Winterthur Technology Group, a 100% subsidiary of 3M, is one of the world’s leading manufacturers of innovative grinding solutions. The group holds a unique position in the market in that it is the only manufacturer that offers the full range of grinding tools and machines from a single source. Its bonded abrasives are used particularly in the automotive, aerospace, tool machine, toolmaking, glass and steel industries especially for the precision grinding of ultra-hard materials.